Optimizing Fast-Charging Strategies for Electric Vehicles

- Blog

Electromobility is facing a key challenge: battery charging times must be minimized in order to increase the acceptance of electric vehicles. This is of key importance as, alongside range, charging time is one of the most important factors for user satisfaction.

However, charging is a complex balancing act: On the one hand, sufficient energy must flow into the battery as quickly as possible to ensure a sufficient range; on the other hand, the cells must not be excessively aged by the charging process, or even risk thermal runaway.

Battery developers are faced with the challenge of taking all relevant factors for safety and cell integrity into account when developing the fast-charging strategy. It is crucial to achieve the planned cell service life to ensure an adequate residual capacity of the battery even after many years.

The expectations of drivers who are used to short refueling stops with combustion engines can lead to some problems when switching to electromobility, as the charging times for electric cars are still significantly longer. Various approaches are being pursued in an effort to promote the widespread acceptance of electric vehicles. One promising strategy is to conduct material studies to further optimize batteries for faster charging. The focus here is on investigating the effects of different materials on fast charging while improving energy density. However, it should be noted that some materials can also have a significant impact on battery aging, which is a challenge that needs to be addressed.

This is precisely where the use of simulation becomes increasingly important. It makes it possible to develop and optimize fast-charging strategies cost-effectively by using accurate electrochemical simulation models to get closer to the performance limits of the respective cells. Through simulation, developers can predict the internal behavior of the battery under different conditions and thus ensure that fast charging is both fast and gentle on the battery.

The battery can only reach its maximum performance under optimum conditions. Very high performance is possible within the ideal temperature range of the battery, but outside this range it decreases drastically.

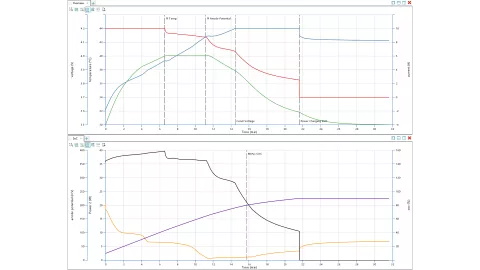

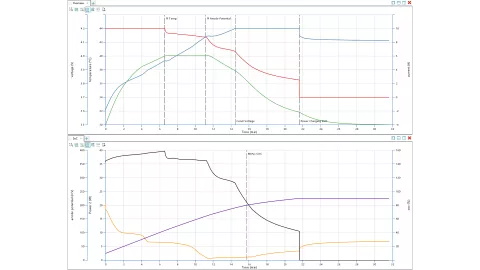

The charging speed also depends on the battery's current state of charge. If a lot of energy is already stored in the battery, the charging power must be significantly reduced to ensure that the battery does not age excessively. The efficient development of a fast-charging strategy therefore involves considering where the optimum range lies and how to keep the battery within this optimum window during the charging process. In summary, we can say: To significantly increase battery life, an optimal charging strategy should be selected to charge the battery as quickly as possible without significant aging effects, and the state of charge should always be maintained between approximately 30 % and 80 %. When charging the battery close to its operating limits, many electrical and chemical parameters must be taken into account.

Here are a few examples:

- Maximum power: The maximum power provided by the power grid.

- Maximum voltage: Electrolytes and cathode materials decompose above the maximum allowable voltage, causing irreversible damage.

- Maximum charging current: Each charger can only provide a certain maximum current.

- Maximum cell temperature: Cell material degrades above the maximum allowable temperature. Significant aging will result.

- Minimum anode potential: Lithium plating occurs at potentials below 0V.

Grid Integration

The electricity grid infrastructure represents a limitation for the expansion of e-mobility. It is necessary to estimate in advance when and at what intensity charging can take place in order to avoid overloading the grid and to offer customers the shortest possible charging time. Power grid simulations can be carried out with simulation solutions such as AVL CRUISE™ M. A grid model makes it possible to simulate and control grid behavior and test various problem cases. For example, when many cars are charging at the same time or too little energy is being generated.

Aging Condition of the Cell

The age of the battery cell plays an important role in the charging strategy. While new cells can absorb and deliver more power, older cells must be protected to ensure the safe operation of the battery system. Developers are confronted with the balancing act of taking aging conditions into account in the strategy, while at the same time still getting the maximum possible performance from the battery.

It is crucial to gradually adapt the strategy for the aging cell and to take the aging state of the battery into account accordingly. The battery passes on the information about its aging condition to the charging station, whereby the charging power is always adapted to the aging condition.

Compared to the test bench, the simulation of electrochemical models offers a unique insight into the inner states of the battery cell that would otherwise remain hidden. These models provide important information about cell parameters, some of which cannot be measured, such as the anode potential, which plays a decisive role in the selection of a safe fast-charging strategy. With this information, developers are able to push the limits of the cell without damaging it, as the anode potential is closely linked to aging processes at the anode.

An anode potential that is too low leads to severe, non-reversible aging (lithium plating) of the battery anode. By simulating a validated electrochemical cell, charging strategies can be optimized to use the maximum power of the battery without reducing the anode potential too much or exceeding thermal limits. The main factors for consideration are the charging curves and how they are stored in the battery management system to enable fast charging without overstressing the battery.

CRUISE M is ideal for optimizing the charging strategy, as a large number of variants can be simulated in a very short time in order to arrive at the correct charging strategy quickly and efficiently. The use of half-cell measurements as the basis for models, in combination with material studies and impedance measurements, makes it possible to calculate a validated cell model and thus also the anode potential using the model equations. This approach provides a precise method to understand and minimize the impact of the charging strategy on battery aging.

Stay tuned

Don't miss the Simulation blog series. Sign up today and stay informed!

Like this? Maybe you’ll also enjoy these…

Stay tuned for the Simulation Blog

Don't miss the Simulation blog series. Sign up today and stay informed!