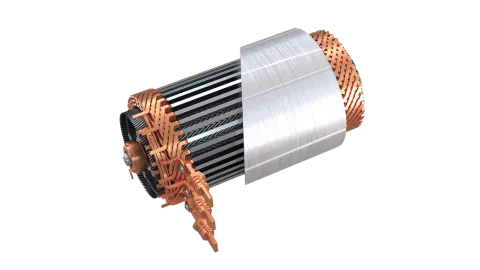

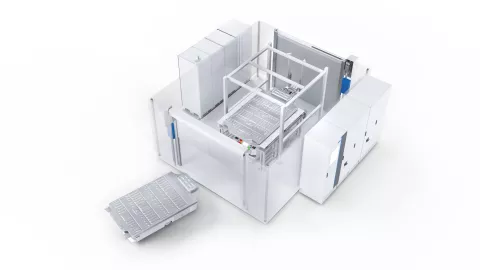

Leveraging our extensive expertise in R&D and production testing, we have developed a highly reliable and robust test system that improves product quality assurance (OK/NOK) for electric motors. This innovative system streamlines test processes, significantly reducing test time and total cost of ownership. Unlike conventional e-motor end-of-line (EoL) testing solutions, our system eliminates the need for a dyno, e-motor cooling and traditional current, voltage and power measurements by measuring forces directly. The entire process - from mounting the e-motor to completing the test - takes less than a minute and delivers results at a fraction of the cost.

| Application | Designed to deal with high and very high production volume in all mobility industries. |

|

E-Motor Handling |

Fully automatic |

| Takt time | Down to 60 seconds |

| Measurement principle | Direct force measurement |

| Signal frequency | Up to 20 kHz |

| Derived measurement values |

Material and assembly defects |

| DC power source | For up to 1,200 V |

| Test cell footprint | About 8 m² |

Piezoelectric Measurement Principle

Our innovative and patented test system utilizes the piezoelectric effect of crystal sensors. The e- motor is mounted on the dynamic force sensor plate with embedded piezo crystal sensors. The quality check of the e-motor is done by measuring the forces during a predefined test without any load. From this, the necessary evaluation parameters such as cogging torque, torque ripple, imbalance, bearing forces, friction, NVH and much more can be assessed.

More Than Just OK/NOK: Reveal Additional E-Motor Phenomena

The piezoelectric matrix makes e-motor phenomena visible in a way never seen before - beyond current, accelerometer and strain gauge technologies. In addition to torque and other conventional signals, even further e-motor phenomena can be derived from the measurement result, i.e. the system solution provides more data than required for a pure OK/NOK evaluation. This data can be used together with other production data to determine optimization potential for the entire production line and even the product design.

Quality will decline if it is not continuously improved, at least at the speed at which technology advances. Our innovative measurement method opens up new ways of fault detection and data evaluation for testing e-motors in all industries. AVL E-Motor TS™ EoL Unloaded significantly improves quality through fast and reliable testing.

– Ferdinand Mosbacher, Senior Solution Engineer, AVL List GmbH