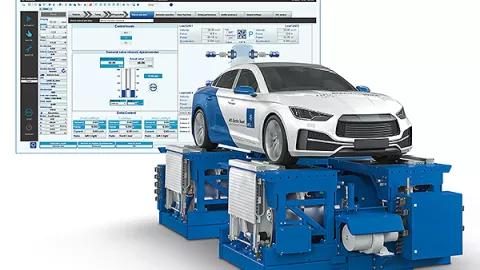

Based on a comprehensive needs analysis, we prepare an engineering study together with you to determine the best course of action. This study considers hardware, electronics and the heart of the chassis dynamometer, the controller. Based on this study, we give you recommendations on how to proceed. If you decide for a modernization, our team executes it.

- Engineering Study:

- On-site check of existing chassis dynamometer by AVL engineer

- Documentation post-processing by AVL

- Aligned workshop to evaluate requirements and discuss options

- Recommendation for/against modernization

- Budgetary modernization quote

- Modernization execution and handover

Engineering Study

Using the detailed AVL Engineering Study Guideline, an AVL engineer thoroughly inspect your existing chassis dyno test system. The engineer will check the configuration and functionality of the entire dyno hard- and software including cables and sensors using standardized checklists. A documentation with pictures will be created.

Customer Workshop

The results of the study are discussed with AVL and the client in a workshop. Open questions about the study or the procedure can be clarified with the respective experts at this meeting. The AVL experts explain their recommendation for go/no go. In the case of a go recommendation, there are already initial concepts for concrete implementation that can be individually designed together with the customer.

Execution

The modernization is carried out by trained AVL experts. Depending on the recommendation, controllers, measuring devices, sensors or other hardware are replaced. All current safety standards are taken into account and the technical documentation is brought up to date. After successful completion of all work, the overhauled and accepted testbed is handed over to the customer.

The modernization of chassis dyno testbed has been my passion for 20 years. Exactly this experience, as well as our well-functioning and interdisciplinary team, makes it possible time and time again to inspire our customers with an amazing cost-benefit ratio of a modernization.”

– Peter Marter, Technical Sales Support, AVL Zöllner GmbH