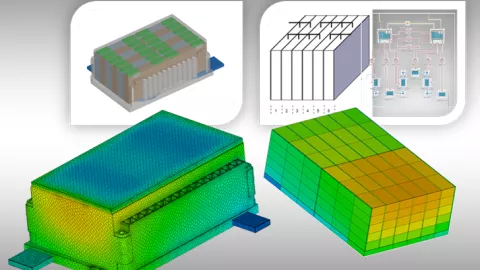

When developing a battery for an electrified vehicle, temperature presents a particular challenge: If the temperature drops, performance decreases and charging problems may occur. Elevated temperature levels can lead to overheating and damage to the battery. Ultimately, this can even lead to component failure. This illustrates the close connection between temperature and performance, operational reliability and battery lifetime.On a real battery pack, the internal condition of the battery can only be examined to a limited extent or with considerable effort. This makes more detailed analysis and evaluation difficult. However, simulation can be used to accurately predict the electrical and thermal behavior of the battery at any point of interest.Depending on the phase of the development process, different solutions are required when developing your battery pack. Typically, you might start by creating a concept on system-level, followed by detailed design studies using 3D-CFD. Detailed component design is about thoroughly analyzing the battery in 3D-CFD. This is then verified on system or even the entire vehicle level.In this webinar, we will show you how AVL eSUITE™ facilitates the switch between individual simulations and development steps. Conveniently, the tools have the same look and feel. In addition, a common simulation environment ensures model consistency and access to a shared material database and parameters. This allows your entire team to collaborate efficiently and ensures the same starting point for everyone.