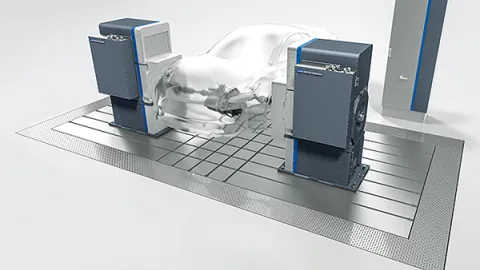

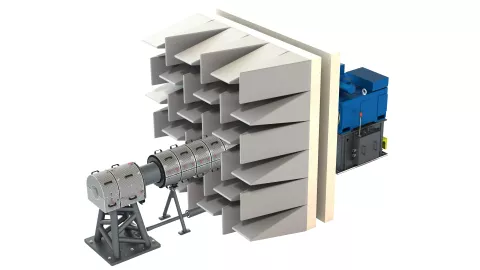

Our modern propulsion test systems are built to validate any kind of propulsion system with different types (e.g. 2WD, 4WD), speeds, torques, and power classes, as well as voltage and current levels in electrified propulsion systems. The dynamometers are speed and torque to the propulsion system, which emulates real-world driving conditions, road data replication, or time-lapsed testing. The optimized toolchain of the AVL hardware and software significantly reduces the duration of the design and validation process. Tests can be executed in an early development phase (frontloading) using the proper virtual environment. This minimizes the risk of design changes in a later stage of the development process.

Our AVL PUMA 2™ automation software adds even more value, since the software synchronizes measurements from every device. This high level of data quality – combined with the system’s precise measurement and control and simulation capability – enables our customers to develop propulsion systems within a reduced timespan, by performing real-world driving maneuvers or energy consumption tests without having the vehicle available.

Nothing is more constant than change. Propulsion system architecture and components have changed dramatically in recent years. Consequently, use cases and applications have also changed. AVL has always been able to design the right solutions for our customer needs. Meaning our customers can focus on their development and trust their measurement results.”

– Dr. Klaus Pfeiffer, System Line Manager, AVL Deutschland GmbH