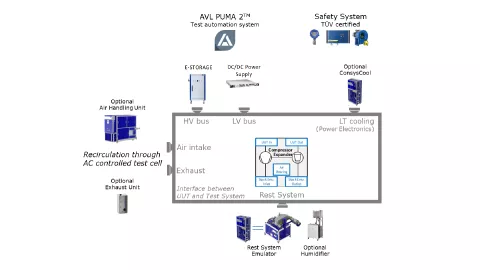

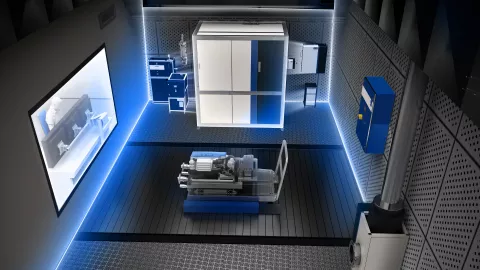

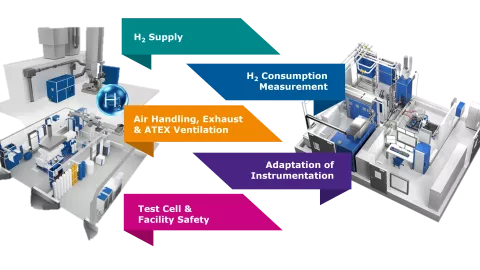

Modular approach

AVL BoP testing solutions are modular and tailored to customer-specific R&D requirements targeting future applications in the automotive, aviation and marine industries. This modular approach delivers high flexibility to cover every aspect of the BoP development process and a high degree of upgradability for seamless adaptation to evolving R&D demands.

Solution Consultancy

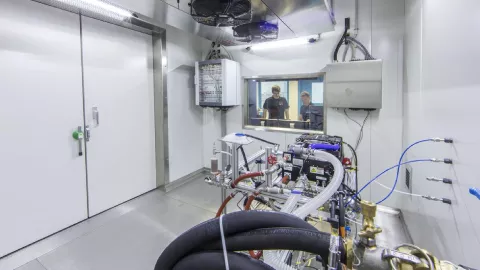

With a proven track record of more than over two decades of fuel cell experience, AVL’s competence covers the entire BoP development process, from target definition through the engineering phase to turnkey solutions for a wide range of R&D requirements. Guidance along the entire process by AVL fuel cell experts leads to high-end, customer-specific BoP testbed solutions.

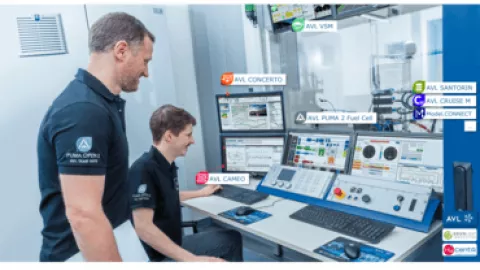

AVL PUMA 2™ Fuel Cell

AVL’s real-time automation system is the perfect match for the entire BoP development program. Its flexibility and compatibility allows seamless exchange of use cases and test procedures across all testing environments and offers simple interface modification for any given use case. The remarkable interplay with AVL’s proven toolchain and the given data consistency across all testing environments makes it the perfect tool to optimize and accelerate the BoP development process.

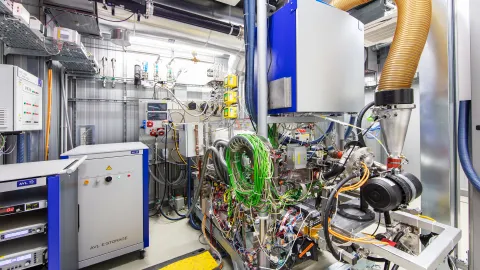

Use Cases

AVL BoP testing solutions are optimized for a wide variety of use cases, e.g. performance characterization, efficiency mapping, model verification and durability testing. This extensive portfolio, combined with AVL’s profound expertise in component and system testing, makes AVL an ideal innovation partner within the framework of BoP development.