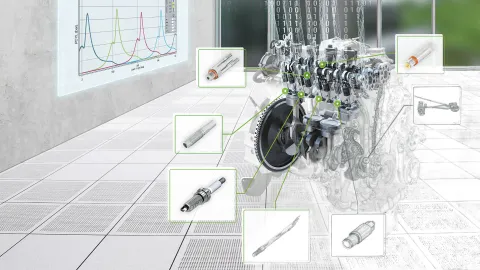

Our pressure sensor portfolio for combustion analysis consists of a large number of pressure sensors for various measurement tasks. They can be used for research, development and to monitor all types of internal combustion engines. Our sensors follow the highest quality standards for any piezoelectric sensors, offering supreme measurement accuracy. A large spectrum of accessories completes the sensor portfolio. Based on the unique gallium orthophosphate crystals grown by the experts at our Piezocryst Advanced Sensorics labs, our pressure sensors are suitable for a wide range of applications. From racing to commercial vehicles and passenger car engines, these pressure sensors are best-in-class products built by a single supplier.

Engine monitoring and combustion analysis - our pressure sensors can be mounted in almost every possible mounting situation that is subject to extremes of temperature and pressure. Whether it’s cylinder pressure, intake and exhaust pressure or fuel pressure measurements that you need to conduct your combustion analysis, our sensors can help. Robust, accurate and stable, our sensors come in a range of sizes for different applications. A complete range of accessories is available for maintenance, mounting and machining, in order to fully exploit their potential.

Brochure Sensor Catalog

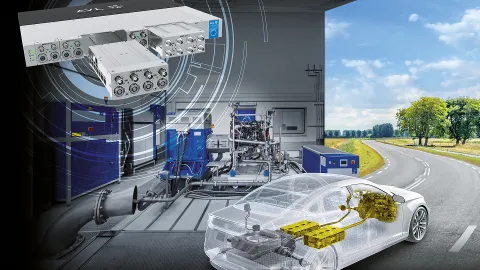

DownloadMaster your measurement accuracy with our wide range of comprehensive combustion analysis tools available on AVL Experience Cloud. This interactive showroom offers future-proof automotive hardware solutions. Use AVL Experience Cloud to conveniently purchase our products:

- Explore the latest features

- Learn more about our devices and accessories

- Get one-on-one support from international success managers

- And much more