7 Trends in Automotive Sustainability

- Expert Article

Martin Rothbart

Senior Product Manager, Energy & Sustainability

For more than four years, Martin has been responsible for business development in the areas of energy, hydrogen, alternative and synthetic fuels as well as the sustainability in the product lifecycle. That includes predictions and the analysis of future market potential in various global regions.

Read here about the seven trends that highlight the automotive industry's efforts to achieve sustainability goals by addressing emissions across the entire value chain and adopting greener energy sources and production practices.

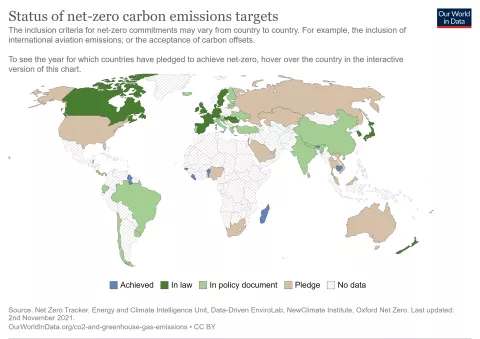

In the center of all our activities is a pathway to CO2 neutrality in the future. Many countries and regions have already stated their target on CO2 neutrality. The European Union and Japan plan for carbon neutrality in 2050, China in 2060 and India in 2070. The United States have set a target to reduce their CO2 output by 50% until 2030. "The two-degree target from Paris remains within reach," said lead author Roger Pielke Jr., professor of environmental studies in the Journal Environmental Research Letters. The world needs to take on the challenge of deep decarbonization, however CO2 neutrality is influenced by other boundary conditions and factors.

Working against net-zero CO2

The COVID-19 pandemic and armed conflicts have shown the fragile global energy supply system. Energy security gains higher importance in the public perception. In the short term, it might be contradictory to the CO2 reduction targets. Zero-carbon primary energy sources, like solar and wind, are bound to an intermittency respectively lower availability compared to their fossil counterparts. The energy transition became part of the 'energy trilemma' as BP's chief executive Bernard Looney has put it-delivering secure and affordable energy when and where it's needed while raising investments in renewables and other low-carbon energy solutions.

We need to provide the world with the energy that it needs today. And at the same time, we need to accelerate the energy transition.

- Bernhard Looney, Chief Executive, BP

Working in favor of net-zero CO2

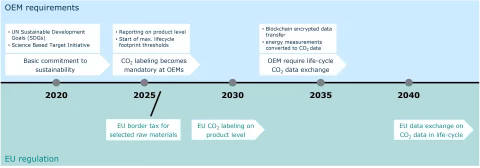

Environmental Social Governance (ESG) regulations as well as carbon taxation and carbon trading systems are setting tighter guardrails for the sustainable future. As an example, the Carbon Boarder Adjustment Mechanism (CBAM) of European Union regulates the CO2 taxation of certain raw materials when imported into the EU from 2026 onwards. The CBAM and other CO2 related regulations favor a global green material trading system.

At the end of the day, we're a molecule company, not an electron company.

- Darren Woods, Chief Executive, ExxonMobil

Currently the EU imports over 57% of its primary energy from outside of Europe. This will also be the case in future, but with renewable energy. Therefore, there are several plans for renewable energy generation projects in renewable „rich“ regions (e.g. North Africa, South America). Renewable electricity is produced and transferred to the energy-demand centers like Europe. There are projects planned with direct transfer via high voltage electricity lines, nevertheless most projects are targeting for a conversion to molecules. That means hydrogen or synthetic fuels (e-fuels) are produced with the renewable electricity. Long distance transport and seasonal storage of energy is usually based on molecules (hydrogen and e-fuels).

It is important to note that all sectors, including industry and chemical sectors, have major demand for renewable energy components. A conversion from ‘green electrons’ into hydrogen or in a second step into synthetic hydrocarbons deliver valuable hydrocarbon molecules outside the transport fuel product molecule range. The market demand from non-transport sectors (especially chemical industry) has a huge potential to drive volumes and price for synthetic transport fuels. Within the transport sector, any available synthetic energy carrier will be used first where the replacement of fossil fuels is most difficult e.g. aviation and marine.

First pilot projects in South America, North Africa and Australia show the urgent need of molecules in the future global energy trade system. The future of the long distance energy distribution will be hydrogen based energy carriers and its derivates. All the conversions involve significant losses. However, it enables the transport with vessels or pipelines, like in the fossil distribution and storage structure of today.

The automotive industry is used to improve vehicle emissions and powertrain technology towards the legislative targets. That approach might change with the life-cycle CO2e application. The OEMs, in particular in Europe, are starting to request from their supply chains to commit to CO2e targets and measures it much earlier than regulation is demanding for it. Supplier for the European automotive industry are already asked for committing to the OEMs sustainability targets. For 2025 CO2e labeling of products, including reporting CO2e on product level and application of maximum footprint thresholds become mandatory. In the long-term manufacturers will require CO2e data exchange using energy measurement and encrypted data transfer.

The increased reporting requirements are accompanied by CO2e reduction plans and roadmaps for each supplied component.

The green mobility strategy of automotive OEMs will insist on CO2 reporting on product level much earlier than the EU regulation.

- Martin Rothbart, Senior Product Manager, Energy & Sustainability, AVL

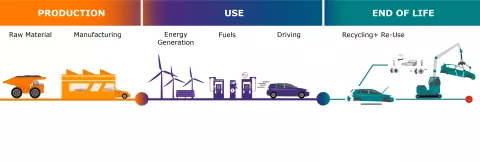

In order to limit the greenhouse gas (GHG) emissions in the transport sector on a global basis, we need to address all aspects of the automotive industry from the production to the use phase as well as recycling. Raw material extraction and production of a battery electric vehicle causes significantly higher CO2e emission than the production of a conventional vehicle. Methods for raw material mining and energy intense production steps are main driver of the footprint in the first life-cycle phase. The use phase of the battery electric vehicle (BEV) shows tremendous benefits in GHG emission compared to its conventional counterpart. Nevertheless, efficiency improvement measures can be applied. Most examples in publications focus on the CO2e reduction potential of the battery, as there is still the largest improvement potential among all components (see Sams et.al., Design-to-CO2 Using the Example of Traction Battery Development, MTZ 9/22). Nevertheless other components like the electrical drive unit (EDU) has sustainability topics to address and can therefore contribute to the CO2e reduction in the lifecycle.

By increasing E-Motor speed with a high-speed-EDU system up to 33 % of CO2e can be saved compared to a low-speed motor system.

- Wilhelm Vallant, Senior Product Manager Transmission Systems, AVL

Considering a base BEV vehicle with an energy consumption of 18 kWh/100 km and an EDU efficiency of 90 %, an increase of 5 % in the EDU efficiency can save almost a ton of CO2e over the life-time usage of 250,000 km. At the end of first life of the BEV components the reusability, 2nd life application or recycling options are strongly influenced if proper design guidelines were applied.

A future proven EDU concept needs to comply to a sustainable design to reduce CO2e footprint and increase efficiency in the life cycle. Design-to-CO2e and design-to-multi-life-cycle needs proper methodologies and guidelines in place.

We should tax every company's carbon footprint and the carbon footprint of every building and home, to incentivize people to reduce their carbon footprint.

- Philip Kotler, American marketing author, consultant, and professor emeritus

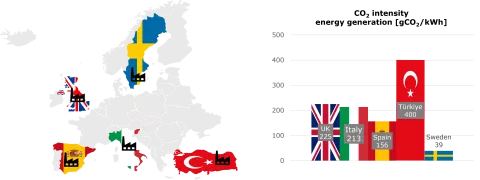

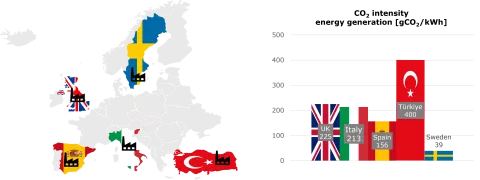

For many years globalization has forced the movement of production to countries with lower wages. Focusing on Europe there is a north-south difference in labor cost per hour. With the shift of production to low cost countries the CO2e occurrence was shifted as well. Countries with lower wages have as well the tendency of higher CO2e in production. When shipping the finished goods back to the high cost respectively consumer countries the CO2e is “imported” back.

Where OEMs increase focus on CO2e reduction in their supply chain, country specific CO2e footprints might lead to different pricing for parts in the future. That might create a reverse trend and triggers a shift of productions to countries with lower CO2e footprint.

Following that thesis the chart reflects the CO2e intensity of selected European countries. In future Sweden usually on the high-labor-cost-side might become an attractive production location for future CO2e lean manufacturing.

If you can't measure it, you can't manage it.

- Peter Drucker

In terms of methodology the CO2e assessment will evolve in the future. ESG and CSRD regulations already open the pathway to report the portion of measured CO2e in the Scope 3 upstream emissions of a company. In the mid-term all important production steps will be equipped with energy consumption measurements which are converted to real time CO2 equivalents. The measurements are interlinked with a digital twin for proper CO2e modeling and energy-based control and scheduling of the production. The smart combination of real-world-data and simulation reduces the iterations needed to reduce CO2e in the production.

The example shown in the chart references to the AVL Battery Innovation Center (BIC). The BIC is a small scale batter production facility for pilot manufacturing of battery packs as well as small series manufacturing of battery packs. All production steps are equipped with energy measurement devices. The sample measurements are recorded at the stacking robot. With those energy measurement devices energy consumption is used as primary data for calculating the CO2 footprint of that manufacturing step. The data is transferred and merged with simulated data for defining the carbon footprint of the entire battery manufacturing. The information gained is used to optimize the CO2e in manufacturing. In addition it is used for the next development projects already in earlier development phases as an additional input.

Batteries placed on our (EU) market, regardless of their origin, they will be sustainable.

- EU Commission Vice-President Maros Sefcovic

"Design-to-CO2e" as a holistic approach in the course of systems engineering means a transition from an original focus on "design to function" and "design to cost", as also represented in value-analytical methods or quality function deployment, to the additional dimension of CO2 equivalent over the life cycle. (Sams, C.; von Falck G.; Sorger H.: Cost Engineering as an Essential Part of Systems Engineering. In Systems Engineering for Automotive Powertrain Development. Schweiz: Springer, 2021). Existing methods and tools from total cost of ownership and life cycle costing can be taken as a basis and supplemented by the dimension respectively currency of CO2e.

Thus, this chart shows an ideal-typical profile of CO2e influenceability, determination and actual occurrence over the product life cycle of a battery electric vehicle, assuming a predefined electricity mix in the production and operating phase. In this context, the different development and validation phases (A, B, C/D samples) are characterized by their great potential to leverage the actual occurrence of CO2e emissions in the phases of production, in-use, and end-of-life. This is also the time when engineering service providers such as AVL, together with the OEM and its value creation partners, can achieve decisive competitive advantages.

The main question to answer is: How can we increase our impact to a maximum to reduce CO2e in the life-cycle as fast as possible.

Whitepaper Carbon Taxation (CBAM)

The Impact of Carbon Taxation on the Automotive Industry: How to manage CO2e in the production with a focus on the Carbon Border Adjustment Mechanism (CBAM)

Related Topics

We are constantly working on new solutions. The following might be interesting for you:

Making the best engineering methods and tools available to solve the task of the century: An Energy System based on Renewables

Understand the present and future energy landscape to take the best decisions for your energy mix

Sustainable engineering from design to end-of-life.

News

Moving steadily into the future: Find out what’s brand new in the field of energy sustainability.

In this webinar Rittmar von Helmolt and Martin Rothbart will discuss possible energy distribution and storage methods and their short- and medium-term feasibility.

As a global society, we are pushing hard to achieve a transformation to net-zero-CO₂ but without loosing energy security and our current living standards. The transformation in the mobility will come at cost, which endangers affordable individual mobility in the future. Doing nothing, however, will generate even higher costs.

Senior Product Manager, Energy & Sustainability

For more than four years, Martin has been responsible for business development in the areas of energy, hydrogen, alternative and synthetic fuels as well as the sustainability in the product lifecycle. That includes predictions and the analysis of future market potential in various global regions.