Find out about the highlights of the latest release in our battery solution area.

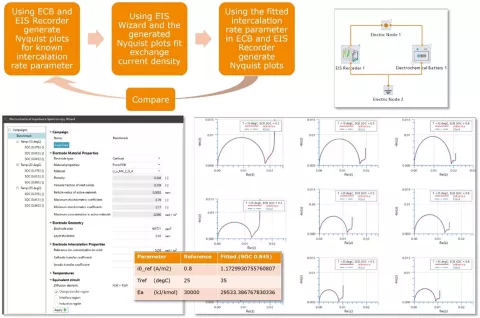

The reference exchange current density, electrode diffusion coefficient and the activation energy can be derived from measured impedance spectra. The EIS Wizard in AVL CRUISE™ M offers a guided parameterization process fitting the electrochemical model parameters. Multiple data sets for different SOCs and temperatures can be loaded from measurements and fitted. The identified parameters are automatically transferred into CRUISE M’s Electrochemical Battery (ECB) component.

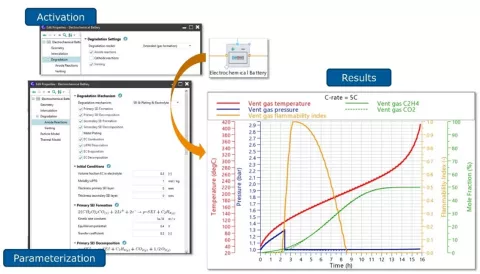

In addition to already available degradation models that consider SEI formation, SEI decomposition, metal electrolyte reactions and metal plating, CRUISE M now also enables consideration of the formation of gaseous products. The new model takes into account primary and secondary SEI formation and decomposition, as well as the evaporation, decomposition and combustion of the electrolyte.

The CRUISE M Battery User Coding Generator enables the modelling of user-defined gas formation.

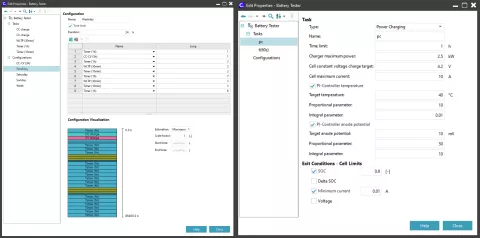

In order to be able to simulate battery life efficiently, driving cycles (e.g. weekly profile) are typically cycled over the course of a couple of years while considerng seasonal environmental conditions. These test scenarios can now be created very easily with the Battery Tester in CRUISE M. The Battery Tester provides visual feedback on the test assemblies including an estimate of the maximum possible physical simulation time. The time horizon of such tests can range from minutes or hours up to weeks, months or even years. Pulse tests, charging events, repeatedly driving a BEV from home to work and having it stand still over a long part of the day. All scenarios can be considered and easily planned and executed with the CRUISE M Battery Tester. Thus, aging phenomena such as SEI layer growth or degradation, as well as li-plating or other aging mechanisms can be observed precisely over the lifetime of a battery.

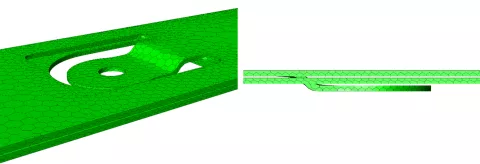

This FIRE M version contains a new method of connecting interfaces that enables heat transfer between two non-perfectly connected domains.This new interface can be created in both a conform and non-conform manner. It is also possible to introduce thermal contact resistance between the two contact faces. By using loose contact interfaces, enforcing conform multi-domain meshing is avoided, which allows the presence of small gaps between the coupled faces.

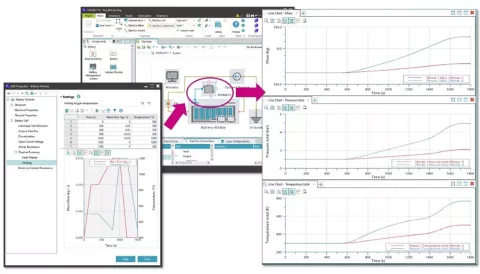

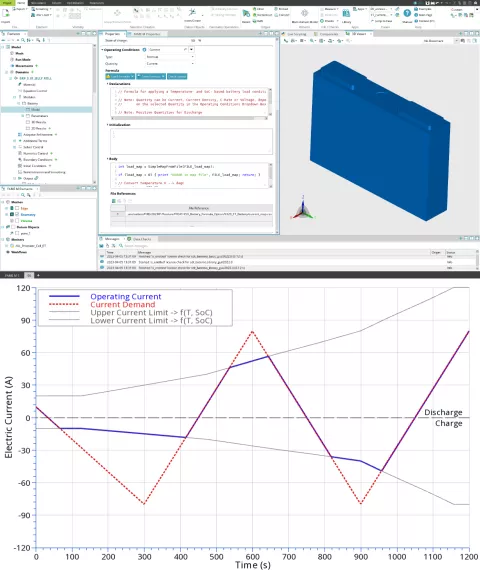

A new formula based option for electrical operating conditions allows the specification of an operating current that depends on temperature, state of charge or anode potential. Besides the "Load steps" and "Profile" options, this third option, "Formula" can be combined with all available model types: electrochemical, electrothermal and Batemo.

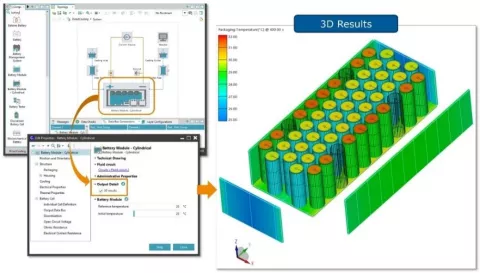

In this version, a number of performance improvements have been added to the cylindrical cell module, as well as the ability to display 3D results.

A new cell clustering methodology is available that enables the option of clustering parallel cells.

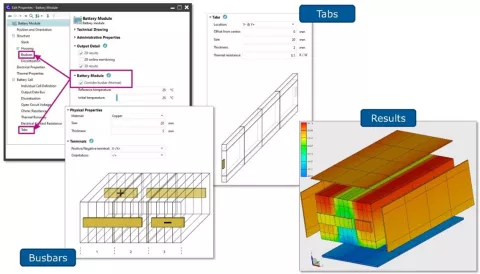

Battery Module component in CRUISE M has been extended to handle the impact of busbars connecting individual pouch (or prismatic) cells.

This version of CRUISE M addresses the formation of venting gases with a new functionality embedded into the Battery Module component. Based on a venting trigger temperature and a given venting gas mass flow, the venting model in the Battery Module component creates a dedicated gas flow connection.