Solid oxide fuel cells (SOFC) are a promising technology for power generation within the context of renewable energy systems. This is mainly due to their high efficiency, fuel flexibility and environmental compatibility.

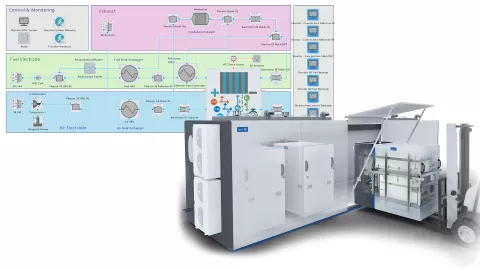

In SOFC development, the engineering effort is aimed at a reliable fuel cell system with maximum efficiency and longest lifetime. To efficiently achieve these goals, a simulation-based development approach is required that covers all aspects from system design to balance of plant (BoP) component dimensioning and operation strategy definition.

Virtualizing key development steps with AVL CRUISE™ M offers the potential for significant time and cost savings. This is especially true when simulation is already used to define the system architecture and select component technologies. In addition, virtual testing of the system for various use case scenarios, such as high altitude operation, leakage, different insulation materials, transient warm-up cycles, and control functions development, can also considerably reduce physical test time.

Watch now

Ales Cvikl

Team Leader Thermodynamic Systems Simulation

AVL Advanced Simulation Technologies