Particle-Based Simulation to Optimize Dishwasher Design

- Blog

Maximilian Flamm

Saba Golshaahi Sumesaraayi

Siddharth Marathe

FIFTY2 Technology GmbH

Dishwashers are one of those common household appliances that can be found in almost every modern kitchen. In fact, they have been a commonly used appliance for decades now. Although we might tend to take them and their functionality for granted, they have been undergoing constant improvements and have come a long way since the first registered patent for a mechanical dishwashing device back in 1850 in the United States. This is thanks to design engineers, who are constantly pushing the boundaries to improve and optimize dishwasher design. Over the decades, not only have dishwasher designs and capabilities been adapted, but the methods and technologies used to analyze and enhance various aspects of dishwasher efficiency have also changed significantly.

The use of CFD simulations to support the development of prototypes is continuously gaining importance, and this is quite understandable. With the help of simulations, it is possible to gain insights regarding physical quantities like the shear forces acting on different dishware placed throughout the dishwasher by the water jets, wetting and temperature distribution within the dishwasher, and the energy required for cleaning. Additionally, multiple design variants can be simulated by adjusting the virtual models, eliminating the need to build physical prototypes or install costly sensors for data collection during experiments.

There are indeed several aspects of dishwasher design that can be analyzed and optimized with the help of simulations. Many of these can be investigated by performing CFD simulations. For example, some of the aspects that design engineers are usually interested in examining can be:

- Optimizing spray nozzles:

It is always important for engineers to know the effect that modifying different parameters of the spray nozzle geometry can have on the overall spray. This can include changing the size, shape, location and number of nozzles along the spray-arms. Ultimately the aim is to ensure optimal distribution of water and cleaning efficiency.

- Improving dishwasher basket and rack design:

An important aspect of improving the overall dishwasher design is increasing the capacity of the dishwasher by utilizing the space inside efficiently. This can include changing the design of individual dishwasher baskets to increase dishware holding capacity and optimizing their placement to increase the total amount of dishwasher racks inside.

- Analyzing the fluid flow through the impeller and in the piping system:

Another possibility with CFD simulations is the analysis of fluid flow in under the hood parts in a dishwasher, like the impeller or within the piping system. By simulating the fluid in such components, one can extract information pertaining to the amount and velocity of the fluid, as well as the forces exerted by the fluid within these components under different operating conditions.

- Optimizing dishware arrangement:

Perhaps the most interesting information from a customer point of view, is knowing the best-practices regarding dishware arrangements within the dishwasher to ensure most effective cleaning of commonly used dishware items. In addition to gaining insights with respect to dishwasher design optimization, manufacturers could also obtain such information from simulations, and easily provide best-practice suggestions to their customers.

PreonLab is a leading particle-based simulation tool for many applications in the automotive industry. However, the advantages of its unique PREON® Technology, which is based on the Smoothed-Particle-Hydrodynamics method, can be extended to simulating many different applications, especially if they involve free-surface flows. In fact, PreonLab’s mesh-free approach and ability to perform single-phase, multiphase and thermal simulations, make it an extremely useful CFD-tool to gain insights and optimize several aspects of dishwasher design.

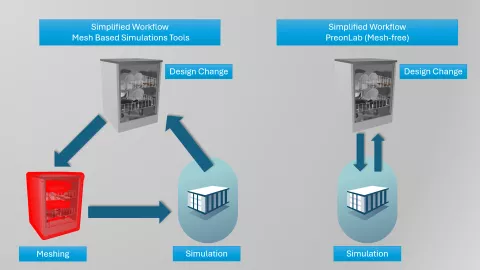

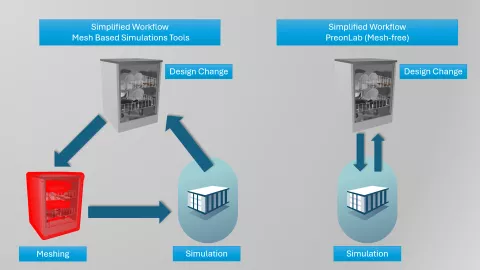

Owing to its mesh-free nature, there is no need to engage time and expertise in meshing all the complex geometries in a typical dishwasher before being able to simulate after every design change iteration. For instance, traditional mesh-based tools require re-meshing any altered CAD geometry after a design change before a new simulation can be performed. In contrast, PreonLab doesn’t require this remeshing step and the old geometry can be simply replaced by the new one and simulation can be started immediately. This is visualized in figure 1. Thus, it is possible to save a lot of time and effort, which is invaluable for rapid prototyping

PreonLab is an all-in-one tool, which takes care of all aspects of simulation and post-processing after geometries are imported into the software. From simulation setup to postprocessing and rendering, engineers can gain insights using the same software.

What’s more, PreonLab supports simulation on CPU and multi-GPU to ensure optimal simulation performance. Its unique implicit formulation adds to the inherent performance benefits of SPH and enables simulation with large timesteps (CFL 1), without compromising on stability. Additionally, advanced algorithms like Continuous Particle Size (CPS) enable adaptive particle refinement and coarsening to efficiently keep RAM and VRAM requirements and computational time to a minimum.

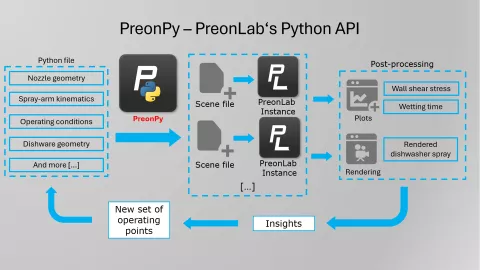

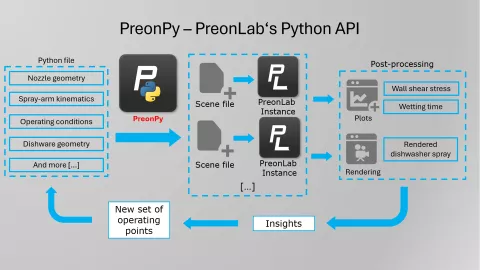

Furthermore, the software is equipped with its own Python-based API called PreonPy. The Preon solver and most of the features found in PreonLab are accessible via PreonPy. It lets you load and save scenes, change properties, run simulations and fetch statistics. This capability is particularly powerful for creating multiple simulation variants, which may be necessary due to changes in operating conditions, nozzle geometries, spray-arm kinematics, fluid properties, or dishware and dish-rack arrangements. Figure 2 illustrates an example of a workflow that can be used with the Python-API, PreonPy to quickly generate simulation variants and improve rapid prototyping strategies.

What Does a Dishwasher Simulation Look Like in Preonlab?

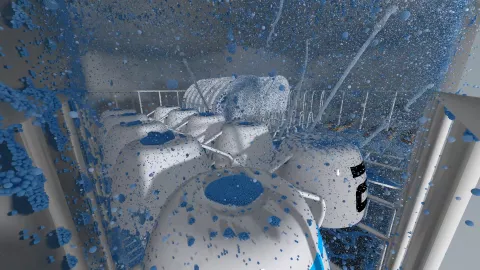

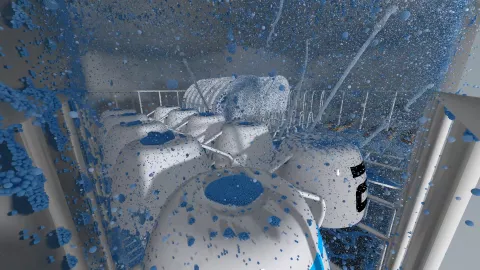

Video 1 shows an example of a single-phase simulation in PreonLab. Fluid particles representing water are emitted from the spray arm nozzles and the water is sprayed over the solid dishware. The simulation result is rendered using the in-built PreonRenderer.

Video 1: Simulation of a Dishwasher in PreonLab

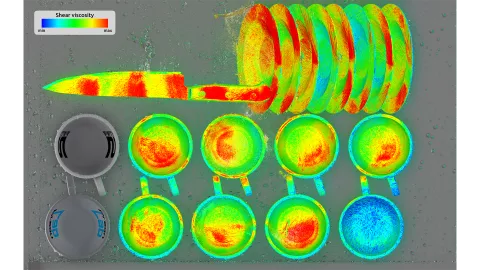

Additionally, it is also possible to perform multiphase simulations to analyze dirt removal. Newtonian and non-Newtonian material properties can be used to simulate food residue on the dishware and the cleaning efficiency of the dishwasher can be investigated. Video 2 shows examples of how water jets clean away ketchup-like and pumpkin-soup-like residue that is deposited on some plates in the simulation.

Video 2: Simulation of a Dishwasher Showing Dirt Removal (Multiphase)

What Insights Can You Gain?

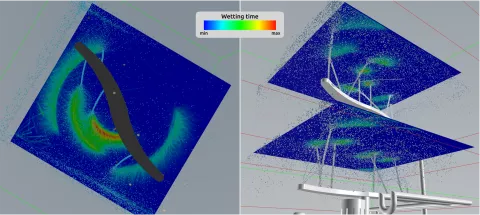

In case design engineers are interested in improving the water distribution by optimizing the shapes as well as the directions of the spray nozzles, they can analyze the flow pattern with the help of Wetting Sensors in PreonLab. In fact, to do so, it is possible to simplify the simulation setup and leave out the dishware from the simulation. Instead, with the help of planes placed above the spray-arms, one can simply observe the wetting pattern for several design variants, by connecting the Wetting Sensors to the planes. Figure 3 shows an example of this. The design can then be adapted in an iterative manner, and subsequently tested on the entire setup once desirable results are achieved in this initial stage.

Typically, the spray-arm kinematics can be easily set up by defining the arm rotation with constant or variable rotational speed. Additionally, it is also possible to consider the motion of the spray arm by considering the forces exerted by the water jets from the spray nozzles. This is possible with PreonLab’s Rigid Body Solver, which can capture the interaction between the spray arm and the fluid. An example of this can be seen in Video 3.

Video 3: Simulation of the Interaction Between the Spray Arm (Rigid Body) and Water (Fluid) Using PreonLab’s Rigid Body Solver

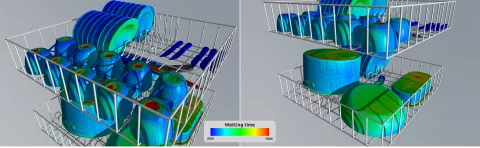

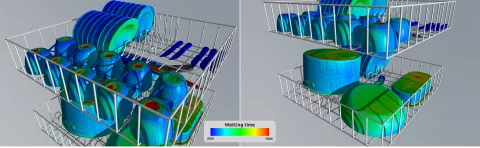

The most important aspect of cleaning efficiency is the distribution of water within the dishwasher and the extent to which it can reach all the dishware. In the simulation, Wetting Sensors can be connected to each dishware object individually, and the instantaneous as well as cumulative wetting of each object can be tracked. Using this information as a foundation, one can determine if changes are necessary to optimize the cleaning capabilities of the dishwasher.

Another aspect is that the water needs to be sprayed on to the dishware with enough force, to remove dirt. At the same time, at no point should any dishware be damaged due to excessive forces. Naturally, not all pieces of dishware are made of the same material and usually have different thresholds, as to how much pressure they can withstand. Additionally, their positioning in the dishwasher basket also influences the interaction with the water jets. In PreonLab, Force Sensors can be used to individually analyze the wall shear stress for every object placed within the dishwasher in the simulation. As a result, it is possible to track the impact of the sprayed fluid on the dishware and ensure that no piece of dishware is damaged while determining optimal operating conditions for efficient cleaning.

Video 4 visualizes the evolution of the wetting patterns and dishware shear stress distribution with Wetting- and Force Sensors.

Furthermore, it can be important to be able to predict the amount of left-over fluid in dishware which can be caused due to imperfect dishware placement. For instance, Figure 6 shows water puddles that have formed on top of cups in the simulation shown in Video 1. Due to the formation of the puddles, not all the water gets drained out during operation. With insights from the simulation, one could consider changing aspects of the basket design or changing how the cups are positioned in the basket to reduce the amount of water that gets collected to form such puddles.

Finally, understanding the thermodynamics of the washing process is crucial for design engineers. Besides flow dynamics, PreonLab also allows for the analysis of thermal effects. With PreonLab's thermal capabilities, engineers can use the Conjugate Heat Transfer (CHT) model for comprehensive analyses. In Video 5, a 60°C warm water jet hits a cup which is initially at 20°C, and the resulting temperature changes of the cup are visualized.

Video 5: Simulation of Hot Water Jets Warming up a Cup During the Washing Process Using Conjugate Heat Transfer in PreonLab

What is shown here is just the tip of the iceberg! Whether it is single-phase, multiphase or thermal, thanks to PreonLab’s extensive simulation and post-processing capabilities, it is possible to analyze and optimize diverse aspects of dishwasher design and cleaning efficiency. It is possible to have an efficient solution to optimize, speed up and reduce the cost of the design process of dishwasher design. Furthermore, thanks to PreonLab’s inherently efficient solver code, no requirement for meshing, multi-platform support, and convenient Python API-PreonPy, users can accelerate their simulation workflow and quickly simulate a wide range of design- and operating conditions as part of their rapid-prototyping strategies.

Running numerous simulations provides valuable insights. If you are wondering how you can keep track of all these dishwasher simulations efficiently, there is a smart, web-based interface to do so. Discover how engineers at FIFTY2 monitor all their PreonLab simulation runs, organize simulation variants, compare results and statistics, and collaborate with teammates using FIFTY2 Technology's newly developed tool: PreonDock.

Stay tuned

Don't miss the Simulation blog series. Sign up today and stay informed!

Like this? Maybe you’ll also enjoy these…

Stay tuned for the Simulation Blog

Don't miss the Simulation blog series. Sign up today and stay informed!