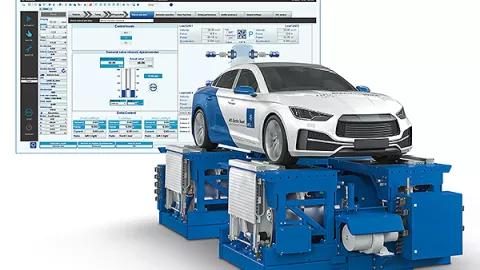

Thanks to the simple integration of measuring devices and simulation models, the system is ideally equipped for testing vehicles with new drive concepts. The excellent axle synchronization in combination with AVL ROADSIM chassis dynamometers allows realistic testing of different vehicle types - from conventional to electrified, from motorcycle to truck.

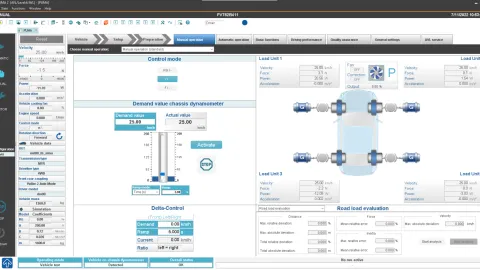

Due to special system features, various applications such as exhaust gas and energy consumption certifications, performance testing, endurance testing, EMC testing, NVH testing, climate testing and much more... can be performed efficiently.

Furthermore, when used in combination with our emission automation system AVL iGEM 2™, the vehicle testbed becomes a state-of-the-art certification lab.

At AVL we also offer software maintenance contracts to ensure the value and stability of our software throughout the entire product lifecycle.

Our systems fulfill all legally required quality procedures for chassis dynamometers (certification) and are tested and approved by worldwide certification authorities (CARB, KBA, TÜV, EPA), as well as being in use at the aforementioned. Based on AVL's automation platform, which has been delivered more than 7,000 times, and thus guarantees the greatest possible future security with regard to the software architecture of the delivered testbed systems, and in combination with AVL hardware the highest accuracy and performance is guaranteed.

– Arnold Berger, Managing Director, AVL Zöllner GmbH