Electric powertrain components, including batteries, fuel cells, e-motors, and e-axles must perform safely and reliably across a wide range of environmental conditions. Replicating such conditions on test tracks or in real-world scenarios is challenging. To overcome these challenges, we have developed our climate chambers. These chambers create controlled environments to test components under extreme temperatures and humidity levels, ensuring their durability and performance.

By utilizing our temperature chambers, you can confidently validate the performance and safety of your electric powertrain components. Our modular design provides the flexibility to test various components in a controlled environment, ensuring that they meet the highest standards of reliability and durability.

Vehicle components must endure a wide range of environmental conditions to ensure reliable performance. Our state-of-the-art climate chambers offer precise regulation of both temperature and humidity, making it possible to simulate harsh conditions from arctic cold to tropical heat.

Our climate chambers are designed to replicate extreme environmental conditions, ensuring that every product undergoes rigorous testing. This capability allows us to validate that your components can withstand the full spectrum of real-world scenarios, providing confidence in their performance under any circumstance. By utilizing our climate chambers, you can confidently validate your components' durability and performance under any conditions.

The climate chambers operate within a specified temperature range, following IEC 60068-3-5 standards. The average temperature is measured in the supply air, without any thermal load, and thermal compensation values are adjusted based on the type of power used. Walk-in and cell test chambers are optimized in size to accommodate various testing needs.

To enhance safety, insulation materials such as polyurethane or mineral wool can be selected. To reduce energy consumption, a domestic water connection can be used to lessen the cooling power required by the chiller, thereby decreasing overall energy usage.

When testing battery prototypes, critical thermal issues can arise. To mitigate potential damage, the chambers can be equipped with a flooding option that protects the surrounding building. Additionally, AVL offers a comprehensive safety system designed to meet Hazard Level 4 or 6 standards for testbeds

Technical Data |

|

|

Temperature range |

–40 °C up to +90 °C |

| Standard rate of temperature change |

2 K/min or 4.5 K/min |

| Battery pack test cell volume |

16 m³ or 22 m³ |

| Battery cell test chamber size |

720 – 1.500 liter |

| Insulation material |

Polyurethane or mineral wool |

| Cooling water flow |

12 °C up to 30 °C |

| Safety version | up to Hazard Level 6 |

Climatic Chamber

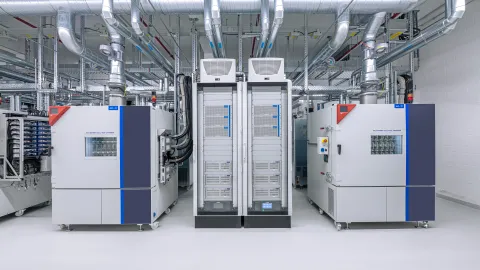

for Battery Cell Testing

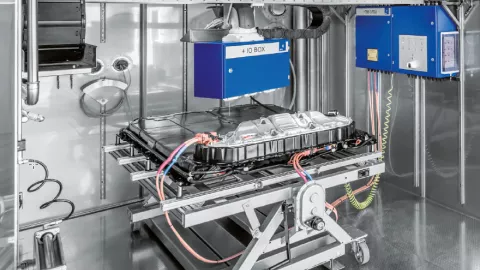

Our battery cell testing climatic chambers are designed to hold up to 12 or 16 cells, making them ideal for rigorous testing. They offer a wide temperature range from -40°C to 90°C and use environmentally friendly CO2 as a refrigerant. The chambers are equipped with a water-cooled system to maintain optimal conditions and ensure even airflow, minimizing temperature fluctuations. With the ability to quickly heat or cool, these chambers are perfect for testing in various scenarios. They are energy efficient, supporting heavy racks with loads up to 500 kg, with an option for 750 kg. Integrated in the AVL Battery Cell TS™, they deliver accurate and reliable test results.

Climatic Chambers

for Battery Pack and Fuel Cell Testing

Our climatic chambers for battery pack and fuel cell testing provide precise control over internal operating temperatures, with a temperature range of -40°C to +90°C. These chambers are available in volumes of 16 m³ or 22 m³, with customizable sizes also possible. They ensure reliable testing results and adhere to IEC 60068-3-5 standards. The temperature gradient for heating and cooling is carefully managed, with average values measured in the supply air, even without a thermal load. For battery prototypes, our chambers can be flooded as a safety measure to prevent critical thermal issues, ensuring protection for both the batteries and the surrounding building.

Safety Systems

Our climate chamber can be designed for EUCAR Hazard Level 4 or Hazard Level 6. They also offer superior safety with flooding options for maximum protection of the testbed and facility. Moreover, we provide customized battery testing safety systems with our automotive testing experience.

Individual Solutions

Our climatic chambers offer a seamless integration into existing testbeds with their unique and application-based design, facilitated by pre-defined interfaces. With their high functional flexibility, these chambers allow for easy and fast upgrades. Each climatic chamber can be tailored to meet the specific requirements of every customer.

Individual Design and

Premium Material

The climate chamber is constructed of high-alloy, corrosion-resistant steel. They are suitable for testing batteries, fuel cells or electric drives. Porthole packages, mounting options and electrical feedthroughs are specifically designed for each test area.

Battery Module Testing

The climatic chambers for battery module testing offer a spacious solution with capacities up to approximately 6 m³ and a temperature range from -40°C to 90°C. Fully integrated into the AVL Battery Module TS™, these chambers allow comprehensive testing of larger battery modules, ensuring accurate simulation of real-world conditions. The integration allows for efficient and precise control, which is critical for evaluating battery performance and safety. With the option of a double side door with window, the chamber can be rotated 90° and has an additional door for even greater flexibility and accessibility during testing.

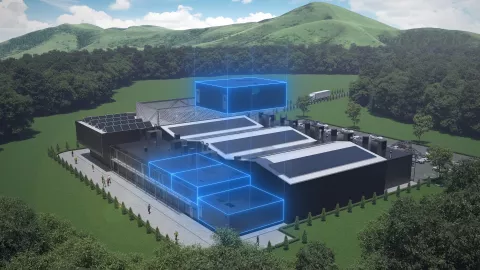

Tech Center Module - AVL Battery Pack TS™

The AVL Tech Center Modules are versatile container solutions designed for rapid and flexible expansion of testing capabilities. These modular units offer a robust and mobile platform for technical equipment and measurement systems, facilitating the swift setup and adaptation of test infrastructures. The tech center module for battery testing serves as a cost-effective and quickly available solution for climatic testing of battery packs and modules. This module achieves a short delivery time by optimizing a standard solution with proven components, ensuring both efficiency and reliability.

E-Motor and E-Axle Testing

Our climatic chamber for e-motor and e-axle testing is engineered for maximum efficiency and sustainability. Its compact design optimizes space utilization while reducing energy consumption and operational costs. A dedicated air conditioning unit precisely controls temperature and humidity, delivering conditioned air through insulated hoses to maintain a stable testing environment. This setup enables flexible test cell configurations while ensuring highly accurate and repeatable results. Designed for seamless installation and maintenance, the system supports reliable, high-performance testing to meet the most stringent industry standards.

AVL ConsysActive Monoblock

Walk-in climatic chambers are the state-of-the-art solution for battery, fuel cell, and other components testing. However, their large size and volume present certain complexities in project logistics, onsite installation, and commissioning. The ConsysActive Monoblock solution is supplied as a single unit, making it easy to integrate into locally sourced enclosure solutions or retrofit existing ones. The complete cooling, heating, and humidification system is designed for seamless and efficient integration. The climate system is thoroughly tested in advance to ensure optimal integration and performance.

AVL Gas Sampling Unit

Testing a battery cell, module, or pack can damage the unit under test, resulting in various EUCAR hazard levels. When Hazard Level 4 or higher is reached, a large amount of characteristic gases are released. Quick detection of these gases can help prevent damage to the climate chamber or the entire testbed by allowing immediate fire suppression measures. The AVL Gas Sampling Unit analyzes the gas composition in the test chamber in less than ten seconds and takes action to address safety issues. Additionally, it can be integrated with existing safety systems to enhance overall testbed security.

AVL has an outstanding and long-term experience in designing testbeds for customer’s needs. Therefore, the AVL Climatic Chambers reach the highest standards in performance, safety, and customer satisfaction.”

– Peter Kerschenbauer, Global Product Manager, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

Tested and Trusted.

AVL Thermal Testing Solutions – Brochure

Keep Cool, Drive Further.

AVL Climatic Chamber Portfolio – Brochure

Ensuring E-Mobility Reliability Through Extreme Environmental Testing.

AVL ConsysActive Monoblock – Solution Sheet

Streamlined Climate Control - One Unit for All Testing Needs.

Tech Center Module – AVL Battery Pack TS™ – Solution Sheet

The fast track to battery testing excellence.

AVL Gas Sampling Unit – Solution Sheet

Application-driven solution for best-in-class thermal development.

For battery (module/pack) testing, we offer complete test systems, stand-alone equipment, or even entire turnkey test labs.

AVL has a wide portfolio consisting of dedicated e-motor test systems, software, tools, and processes to test and validate these modern e-drive systems in shortest time and with highest quality standards.

At AVL, we develop e-axle solutions that can be easily installed without impacting the productivity of your engineering facility.

In the search for green and sustainable mobility, AVL has addressed the challenges of developing and validating automotive fuel cell systems – from a single cell up to complete systems for various applications.

Customer requirements show the need for additional test capacity for ambitious product development plans. AVL Tech Center Modules significantly shorten this process. The flexible, location-independent and easily relocatable modular test system is particularly helpful.

Your success is our goal. This is what we are aiming for and this is how we understand AVL Customer Services since decades. Our goal is not new, but the way how we do it, is constantly evolving.

The primary goal for our AVL Customer Support Teams is, to be a helpful and reliable partner for all kind of questions and issues you might have, when using AVL’s technology.

As a global society, we are pushing hard to achieve a transformation to net-zero-CO₂ but without loosing energy security and our current living standards. The transformation in the mobility will come at cost, which endangers affordable individual mobility in the future. Doing nothing, however, will generate even higher costs.

What kind of cars will we be driving in the future? These and other exciting questions around the topic of "Future Mobility" were addressed by more than 1,000 participants from 25 countries at the international 44th Vienna Motor Symposium. The tenor: Future automobiles will be CO2-neutral.

For his services, Prof. Helmut List was today awarded honorary citizenship of the city of Graz.

AVL generated 1.86 billion Euros in turnover last year – Eleven percent flows into research and development – 60 percent of the turnover is already generated by new technologies.

- EN,

AVL List GmbH has appointed Matthias Dank as new board member and Executive Vice President (EVP). The top manager with international experience was previously at McLaren Applied, where he was Director of Motorsport.