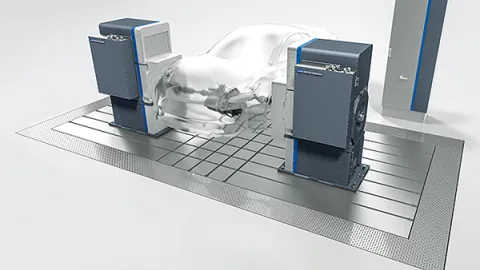

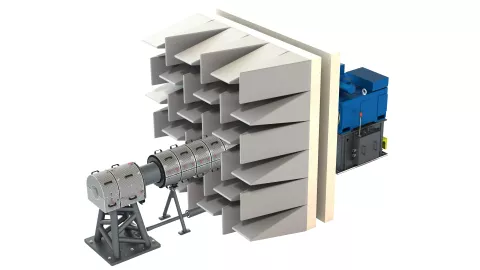

Our modern powertrain test systems are designed to validate all types of propulsion systems, including 2WD, 4WD, and electrified powertrains. They support a wide range of speeds, torques, power classes, and voltage and current levels. The dynamometers simulate real-world driving conditions, road data replication, or time-lapsed testing, providing precise speed and torque control. AVL's optimized hardware and software toolchain significantly accelerates the design and validation process, allowing for early testing in a virtual environment (frontloading).

The AVL PUMA 2™ automation software enhances the system by synchronizing measurements from all devices, ensuring high data quality. This precision, combined with the system’s measurement, control, and simulation capabilities, allows customers to perform real-world driving maneuvers and energy consumption tests without needing a physical vehicle. As a result, propulsion systems can be developed more efficiently, reducing development time and increasing overall project success.

Propulsion system architecture and components have evolved rapidly in recent years, leading to new challenges and opportunities. AVL continues to provide tailored solutions that enable our customers to focus on development with confidence, knowing their measurement results are accurate and reliable."

– Dr. Klaus Pfeiffer, System Line Manager, AVL Deutschland GmbH