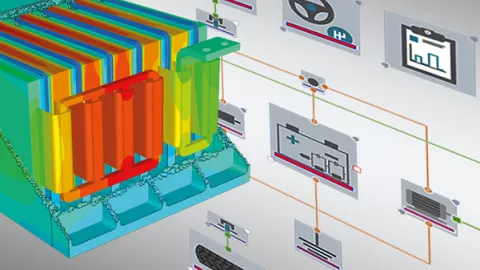

The need to reduce time to market for electrified powertrains is increasing rapidly due to the latest CO2 regulations. Shortening the development time of the battery is a key factor for the entire vehicle development. In order to optimize the performance, efficiency and lifetime of a battery under all relevant usage scenarios, extensive studies are required in the context of the overall vehicle and under different boundary conditions.The virtual integration of a battery pack into the entire drive train and the vehicle permits to consider the battery operating conditions under realistic driving conditions. Only an understanding of the complex interactions between driver, vehicle and environment with the component allows optimization according to these requirements.In our one-hour webinar, Jürgen Schneider, Solution Manager for Virtual Battery Development, and Philipp Wieser, Solution Expert, will convey two essential contents. On the one hand, they will introduce the solution AVL has developed to create detailed, electrothermal surrogate models based on physical components.On the other hand, they will show how the combination of AVL CRUISE ™ M and AVL FIRE ™ M enables such a 1D system model to be generated and calibrated fully automatically, so that also non-experts can model complex thermal and hydraulic processes very precisely.