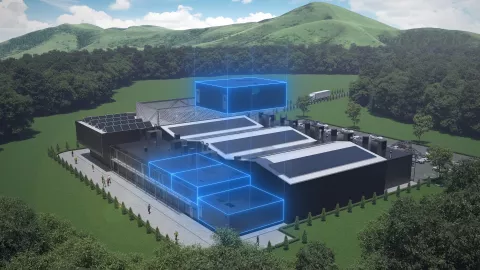

The AVL Tech Center provides comprehensive support for the modernization and repurposing of test facilities worldwide. As technology and industry demands evolve, so do the requirements for testing environments. We are often called upon to upgrade existing facilities to the latest state of the art equipment or to completely repurpose them for new applications.

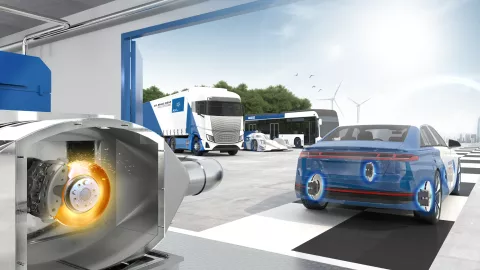

The starting point is often a conventional combustion-related testbed that can be used in the future for developing battery electric powertrains, hydrogen fuel cells, or hydrogen-fueled internal combustion engines. Additionally, we can repurpose these facilities for specialized testing, such as brake wear emissions testing and more.

Our expertise in integrating cutting-edge technologies and reconfiguring existing infrastructure ensures that our customers' facilities remain at the forefront of innovation and comply with the latest industry standards. Whether it is upgrading equipment or completely overhauling the purpose of a testbed, AVL Tech Center provides comprehensive solutions tailored to meet the unique requirements of each client.

Rebuilding a test facility is a complex process that involves addressing a multitude of challenges. It begins with a thorough analysis of the desired workflow, ensuring that the facility's layout supports efficient operations while meeting stringent safety requirements. Additionally, the design must integrate seamlessly with existing infrastructure and account for any constraints.

Detailed engineering involves the development of precise specifications for bidding documents. Preparing submittal documents for building and equipment permits is also a key step, requiring careful attention to regulatory compliance.

Effective project management is crucial throughout the rebuilding process. This includes scheduling, supervising, and documenting all phases of the project. Identify and contract the appropriate partners, continuously monitor progress, and commission and sign off the final result.

Design Engineering

Complete set of engineering documents required for the modernization/ repurposing of the test facilities.

Equipment and Utilities Identification

Inventory of existing equipment, performance calculations, energy efficiency, safety requirements, other regulations, integration possibilities into existing building.

Safety Concept

Gas and flame detection, explosion protection, fire suppression, smoke extraction, pressure relief/blowout panels, lightning protection and more.

Permit Approval

Identify applicable codes for repurposing (i.e., H2), gather information and prepare submission documents.

Cost Calculations

Multilevel detailed budget estimates for cost estimating to derive the necessary information to gain budget approval

Bidding Documents

Biddable package of documents to obtain quotes for construction and prepurchase of long leads → Bid clarification.

We have planned, designed, built and operated our own tech centers in various locations around the world. This has resulted in strong in-house capabilities and a well-established network of partners and suppliers necessary to execute such projects.

Following is a list of the areas of expertise that we deal with on a daily basis:

|

|

By choosing AVL as your partner for your modernization or repurposing project, you can be confident that your testing needs will be met successfully and on time.

Experienced Partner

Our experience from past projects and submissions ensures that you will receive exceptional support for your project.

Extensive Application Knowledge

With both powertrain engineering and test systems under one roof, we have a unique depth of application knowledge.

Integrated Solution of Hardware and Software

With a complete portfolio of test equipment, facility solutions, automation and simulation tools, we can guarantee perfect functionality of the complete test system.

Long Term Service and Support

With a worldwide service organization that extends to complete service and operation of the test facility, we offer a unique level of service capabilities.

AVL established its first tech center a long time ago. Over the years, we have gained extensive experience in designing it around the engineering workflow, based on our own operational experience. For over twenty years, we have also offered our expertise to customers to help them build a new tech center or adapt an existing one.”

– Heinrich Stader, Principal Lead Engineer Turnkey Solutions, AVL List GmbH

Customer requirements show the need for additional test capacity for ambitious product development plans. AVL Tech Center Modules significantly shorten this process. The flexible, location-independent and easily relocatable modular test system is particularly helpful.

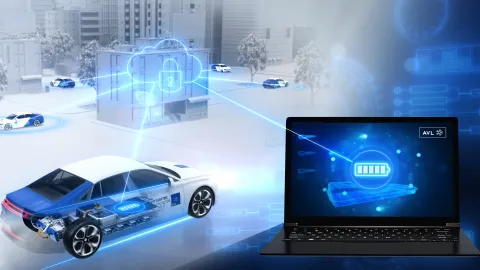

Energy monitoring and load management for your testing facility: AVL EMOS™ is the gateway to energy efficiency and regulatory compliance in the test field.

At AVL, we develop e-axle solutions that can be easily installed without impacting the productivity of your engineering facility.

With the shift towards electrification comes a high demand for test systems that focus solely on e-axles. These test systems must cover the requirements and test standards for E-Motor, inverter and transmission.

For battery (module/pack) testing, we offer complete test systems, stand-alone equipment, or even entire turnkey test labs.

We offer complete test systems for the testing of modules/packs. Learn more about which hard- and software products are included in our test systems.

AVL has a wide portfolio consisting of dedicated e-motor test systems, software, tools, and processes to test and validate these modern e-drive systems in shortest time and with highest quality standards.

WEBINAR - Brake wear is one of the most significant non-exhaust traffic-related sources of particulate matter and, as a result, will be included in future emission regulations. Due to the broad size range of brake wear particles new instruments are required.

In the search for green and sustainable mobility, AVL has addressed the challenges of developing and validating automotive fuel cell systems – from a single cell up to complete systems for various applications.

AVL’s hybrid and engine test systems are highly flexible development environments for testing internal combustion engines and their hybrid components.

Your success is our goal. This is what we are aiming for and this is how we understand AVL Customer Services since decades. Our goal is not new, but the way how we do it, is constantly evolving.

- EN,

AI for optimised energy management of fuel cell commercial vehicles

- EN,

ENX approved: AVL extends its pioneering role in the field of data security

With captivating stories and insightful interviews, we invite you to join us as we embark on the exciting journey of AVL, diving into our rich history and envisioning the endless possibilities ahead.

- EN,

Cooperative model training to predict battery lifetime as a basis for longer durability

- EN,

Fast and high-quality product development

- EN,

The vehicle diagnostics and measurement technology specialist achieved first place at the Styrian ALC awards in the Big Player category