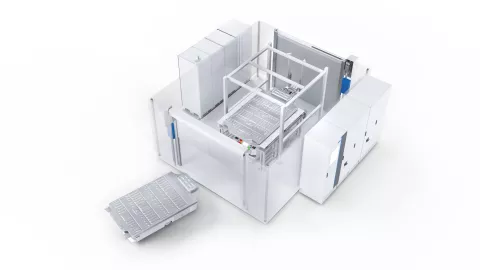

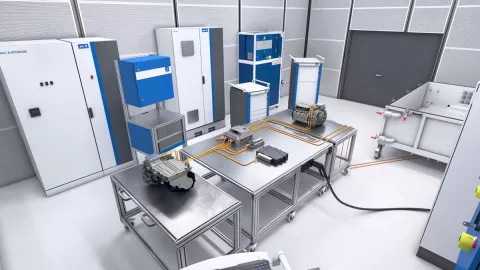

The AVL Battery Cell TS™ can be adapted to a wide range of customer requirements. Typically, our battery cell test systems consist of the following subsystems:

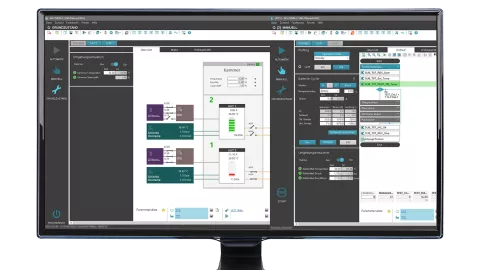

Testbed Automation

Depending on the performance required, the AVL automation system supports up to 64 channels in real time. Moreover, our automation software enables various types of devices to be integrated and controlled fully automatically. → Learn more

Climate Chamber

We offer different chambers with and without humidity. The typical temperature range is between -40 and +90 °C. → Learn more

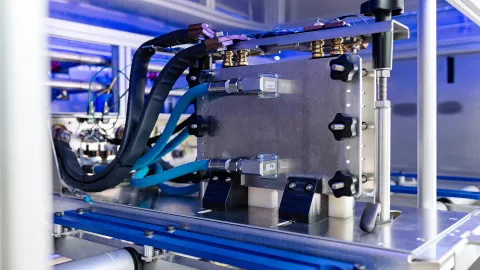

Cell Holder

Cell Holder and Fixture systems are designed for a variety of shapes and sizes, such as coin, prismatic, pouch, cylindrical.

Safety System

We have designed the safety system according to the expected risk level based on our cell analysis database.

Measurement Systems

Based on customer requirements additional sensors for temperature, force and displacement can be integrated.

Greatest Measurement Accuracy

To achieve the objectives of the test procedure, we have developed our products with the greatest measurement accuracy of up to 0.01% FS.

Continuous Real-Time System

Each test channel can be controlled and monitored such that an important threshold of at least 100 Hz depending on architecture is not exceeded.

Regenerative System

To keep energy costs as low as possible, every cycler at AVL is designed to be regenerative so that energy can be returned to the grid.

Global Presence

AVL is represented around the world and supports customers locally with experts on site.

We offer flexible and future-proof solutions for your cell testing challenges with configurable solutions for your individual testing needs. Our innovative approach ensures you stay ahead and achieve accurate results every time.”

– Dominik Strasser, System Line Manager, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

Tested and Trusted.

AVL Battery Testing Solutions – Brochure

Learn more about our holistic battery testing portfolio and solutions.

AVL Cell Testing Solutions – Brochure

To master the heartbeat of the battery. From single channel to automized lab testing.

AVL Battery Cell TS™ – Solution Sheet

Exploring the limits with maximum safety.

Battery Testing for Urban Air Mobility – Solution Sheet

Boost your battery test process.

Success Story – “Valmet Automotive”

Success Story – “Battery Testing for LABCO”

How AVL supported LABCO BTC in entering the world of battery development.