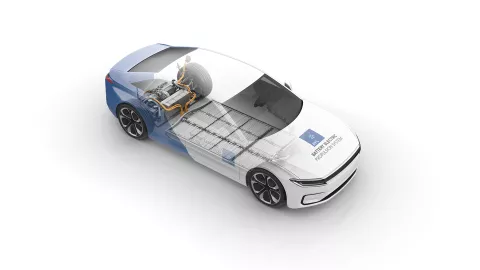

At AVL, we run a comprehensive, continuous benchmarking program for vehicle battery systems. This gives us a deeper understanding of current module and pack technologies, and enabled bay the flip of the well-known V process: Integration and verification go hand in hand with product design and component procurement, and the specification of requirements.

- Continuous benchmarking program for vehicle battery systems

- Reports, test data, workshops with immediate availability

- Four new vehicles per year: from low-budget to luxury xEVs

- All key reference characteristics contain: performance, security, efficiency, operational reliability, costs, producibility, ease of service, technical requirements

New Battery Series Development

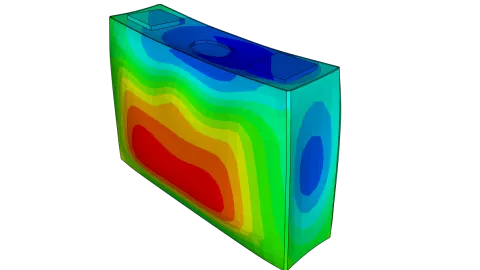

Make use of our development methodology for new battery series – from the first drawing to SOP. It is specifically tailored to current customer requirements and provides you with a proven combination of requirement management, risk assessment, simulation, and validation.

Development of Battery Derivatives

We offer solutions based on model-based system design, streamlined in terms of costs and time, specifically for the development of production and product variants. These deliver benefits for established manufacturers as well as for new market entrants.

Reach Your Objective in Eight Weeks

Our standardized process for the development of concepts for battery modules and packs provides you with advantages in projects under huge time pressure. It takes just eight weeks to get from the idea to the series-ready mainstream concept solution – including all of AVL’s expertise for the various battery applications.

AVL upholds a strong focus on battery design and technology from the cell to large scale production ready energy systems. With the everchanging xEV market, we are continuously honing our strengths for tomorrow’s batteries and customer needs. Recent examples include exceeding thermal propagation regulation time by more than 14x, launching one of the first immersion cooled batteries into production, and utilizing data analytics for early warning anomaly detection.

– Adam Dendrinos, Senior Product Manager Battery Systems