Electric drives are crucial in both Battery Electric Vehicles (BEV) and Fuel Cell Electric Vehicles (FCEV). Innovations in e-drive development are driving deeper integration of inverters, e-motors, and transmissions into a single housing of an e-axle sub-system. This approach minimizes packaging and reduces interfaces but also increases the complexity of testing each integrated component and the entire e-axle sub-system.

We offer a comprehensive portfolio of dedicated e-axle test systems, software, tools, and processes designed to efficiently test and validate modern e-axles in the shortest possible time, ensuring optimal performance and reliability in these cutting-edge powertrains.

Modern e-axle systems are designed to be highly compact, with superior power density and optimized for efficiency, performance, and drivability. E-axle test systems must meet stringent requirements related to service lifetime, performance, and NVH to ensure a comfortable driving experience. Additionally, adhering to strict EMC limits is essential to guarantee vehicle safety.

These test systems must be capable of handling the evolving demands of electric mobility while supporting advanced diagnostics and predictive maintenance. This enhances reliability, minimizes downtime, and ensures peak performance throughout the e-axle’s lifecycle.

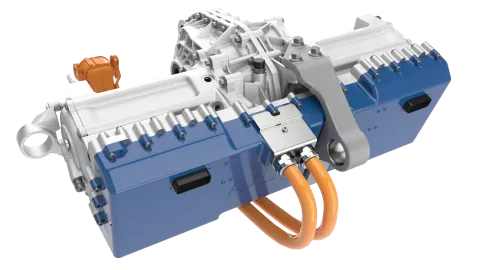

AVL E-Axle TS™ Performance – Light Duty

The AVL E-Axle TS™ Performance is a tailor-made solution for the development and validation of light-duty e-axles, whether single or dual motor. With the shortest lead times, you can quickly start life cycle and thermal endurance testing, as well as electrical, mechanical and thermal property analysis. This test system enables precise performance and functional testing up to 20,000 rpm and 400 kW, supported by a direct drive dynamometer, flexible multi-channel cooling conditioning and a climatic chamber for environmental simulation.

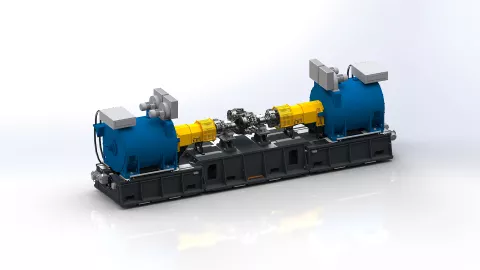

AVL E-Axle TS™ Performance – Heavy Duty

The AVL E-Axle TS™ Performance - Heavy Duty is a standardized test system designed for the development and validation of e-axles in commercial vehicles. Tailored for trucks and buses, it enables comprehensive life cycle testing under realistic vehicle-like conditions. The system supports precise performance and functional testing with capabilities of up to 20,000 rpm and 400 kW. It features a direct-drive dynamometer, flexible multi-channel cooling conditioning, and a climatic chamber for environmental simulations, ensuring the e-axles perform optimally in diverse operating conditions.

Energy Flow Testing

This innovative solution enhances efficiency and optimizes performance through comprehensive testing and validation. It includes electrical range evaluation under various climates, system efficiency validation, energy management during driving, recuperation, and charging. Additionally, it covers strategy verification, road tests, failure mode analysis, EDU performance optimization, and evaluation of electrical auxiliaries and recuperation techniques.

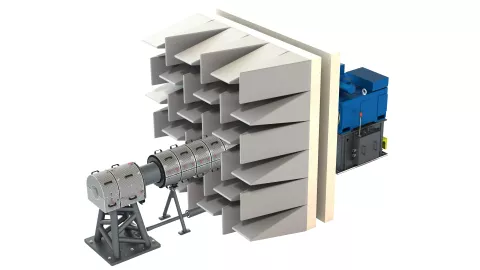

AVL E-Axle TS™ NVH

Our AVL E-Axle TS™ NVH system is designed to redefine silence, comfort, and overall performance in both light-duty and heavy-duty e-axle solutions. With exceptionally low operating noise levels, it ensures superior NVH performance. The system features semi-automatic track width and wheelbase adaptations, enabling high-end NVH development with ease. This innovative solution is setting new industry standards for NVH engineering in both current and future e-powertrains, ensuring optimal performance and maximum user comfort and satisfaction across all mobility applications.

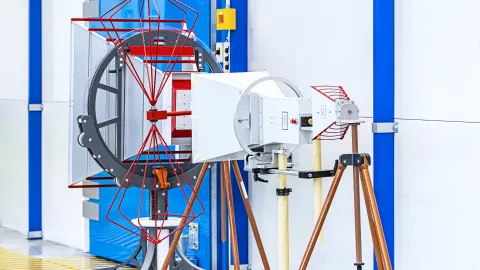

AVL E-Axle TS™ EMC

To measure the electromagnetic compatibility (EMC) of e-drive systems and evaluate their emissions or assess their immunity to interference, specialized EMC test systems are required. Our AVL E-Axle TS™ EMC provides precise measurements and testing in accordance with the CISPR 25 standard, ensuring your systems meet stringent industry regulations. With this solution, you can effectively assess both emissions and immunity of your e-axle components, guaranteeing the reliability and compliance of electric drive systems for future mobility applications.

E-Axle Production Testing

Our End-of-Line (EOL), Conformity of Production (COP), and Quality Assurance (QA) test systems are designed to ensure the quality and security of your entire e-axle production process. These fully automated e-axle rigging systems, integrated with robotic handling, allow for extremely short takt times, reducing them to just 120 seconds. By incorporating these advanced testing solutions into your production line, you can achieve high throughput while ensuring the highest quality standards, improving both the efficiency and reliability of your e-axle manufacturing process.

With our in-house engineering department, we closely evaluate and actively shape the market and innovations in order to provide our customers with the best possible advice and support. Based on this application know-how, we develop e-axle test system solutions that ensure our customers achieve their development goals sustainably and efficiently.”

- Klaus Pfeiffer, System Line Manager, AVL Deutschland GmbH

Our solutions minimize the Total Cost of Ownership (TCO) with pre-engineered systems tailored to service lifetime, NVH, and EMC applications. They offer a compact footprint and reduced running power, ensuring efficient resource use.

We enhance operational efficiency by accelerating productivity and integrating seamlessly into existing automation systems for fully automated testing. Our systems are designed to minimize electrical grid power consumption, significantly reducing environmental impact and supporting eco-friendly operations.

AVL E-Mobility Testing Solutions – Brochure

Tested and Trusted.

AVL E-Axle TS™ Performance – Solution Sheet

Integrated perfection.

AVL E-Axle TS™ Heavy Duty – Solution Sheet

A smarter way of testing e-axles.

AVL E-Axle TS™ NVH – Solution Sheet

Our commitment to silence.

AVL E-Axle TS™ QA / COP – Solution Sheet

Highest Flexibility. Complete Quality.

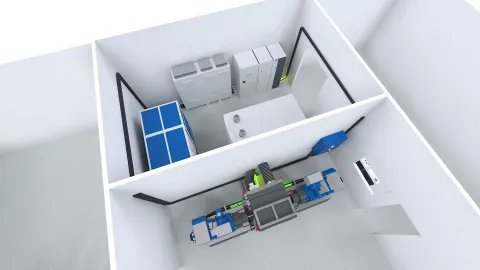

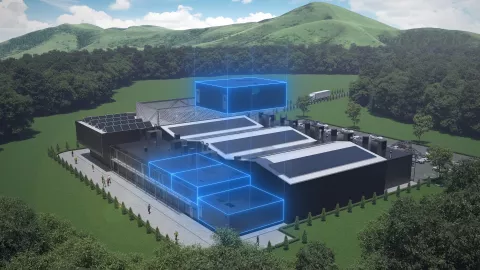

Tech Center Module – AVL E-Axle TS™ – Solution Sheet

The fast lane to ramp up e-axle testing.

AVL offers comprehensive software solutions to optimize your e-axle testing performance. Our holistic approach combines lab efficiency through automation and test optimization via virtualization for faster results.

The advanced data analytics solution using AI extracts valuable insights from various sources. Additionally, our solutions are designed to seamlessly integrate with your existing systems, ensuring a smooth transition.

This will help you get your products to market faster while ensuring high-quality performance. Learn more about AVL’s approach and explore our software solutions to optimize your e-axle testing process now.

AVL’s deep experience with NVH powertrain testbeds allows to provide a high-quality acoustic test environment for e-axles. All components and acoustic enclosures are designed by AVL to ensure excellent NVH performance with minimal sound reflections through simulation-optimized design.

Based on years of experience in research and development, as well as production, we have developed AVL E-Axle TS™ Production. It provides End of Line (EOL) and Conformity of Production (COP) testing for electric drive applications, from passenger cars to high performance vehicles, as well as industrial applications.

Customer requirements show the need for additional test capacity for ambitious product development plans. AVL Tech Center Modules significantly shorten this process. The flexible, location-independent and easily relocatable modular test system is particularly helpful.

The best-in-class automation system for e-motor testing.

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

Intelligent automation, quick and easy

AVL CAMEO 5™ unlocks a new maturity level of calibration and validation in automotive software testing.

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 30

years of experience.

> 4,000

powertrain experts.

> 500

executed powertrain and e-axle projects.

> 45

global technical and engineering centers.

AVL List GmbH received the Global EcoVision Award from WKÖ in the presence of Federal Chancellor Karl Nehammer, Federal Minister Martin Kocher, and WKÖ President Harald Mahrer for the achievements in Hungary.

What kind of cars will we be driving in the future? These and other exciting questions around the topic of "Future Mobility" were addressed by more than 1,000 participants from 25 countries at the international 44th Vienna Motor Symposium. The tenor: Future automobiles will be CO2-neutral.

For his services, Prof. Helmut List was today awarded honorary citizenship of the city of Graz.

AVL generated 1.86 billion Euros in turnover last year – Eleven percent flows into research and development – 60 percent of the turnover is already generated by new technologies.