The automotive world is undergoing a major change. The dominant role of the combustion engine has been displaced by an additional number of new and diverse powertrain concepts flooding the market. Political and economical facts significantly determine the speed and magnitude of the transition. To address customer needs resulting from these market trends, AVL offers a complete testing solution portfolio for both electrified powertrains and combustion engines.

We have more than 40 years of experience in a wide range of production testing applications for internal combustion engines. More than 400 AVL test systems are installed at production sites worldwide. While meeting the continuing ICE testing needs, we have additionally developed dedicated solutions for e-mobility applications. Our QA, COP, and EOL solution portfolio covers the complete range of production testing systems. Depending on the given customer situation, we support the concept definition and optimization and accordingly, deliver from testing components up to full turnkey solutions. All this makes us a competent partner for both ICE and e-mobility production testing.

As the electrification business grows fast, the transition from combustion engines to electrified powertrains occurs in leaps and bounds. Existing manufacturers need to extend and adapt their testing methods and implement a smooth and efficient transition process whereas new entrants in automotive business have to set up respective systems and processes under more and more increasing time pressure.

Today's production testing requires smart-factory-style operation with highest throughput. Flexible testing systems with interfaces to different production data management systems are key. In addition, efficient and reliable testing resulting in high data confidence avoids recalls, which are cost intensive and possibly harm the brand.

- Ideal Partner for a Changing Industry

AVL’s application know-how and project flexibility with global presence and local support teams make us an ideal partner in this diverse and transforming industry.

- New Way of Efficiency

New tools and workflows in the area of system planning, best practice project execution and AI (Artificial Intelligence) supported data evaluation are reducing complexity and effort resulting in highest efficiency.

- High Quality and Availability

The high quality of measurement system secures trustworthy test results. Proven quality of system components and failure proof system design ensures maximum testbed uptime.

At AVL, we see our production testing solutions as an important factor for both an effective production process and high product quality – a major pillar our customers can rely on.”

– Robert Nemeth, Department Manager, AVL List GmbH

We offer a complete portfolio of test systems for electrified powertrains, hybrid and combustion engines. AVL’s End of Line, Quality Assurance, and Conformity of Production testing solutions are supporting you to highly secure your product quality and production process.

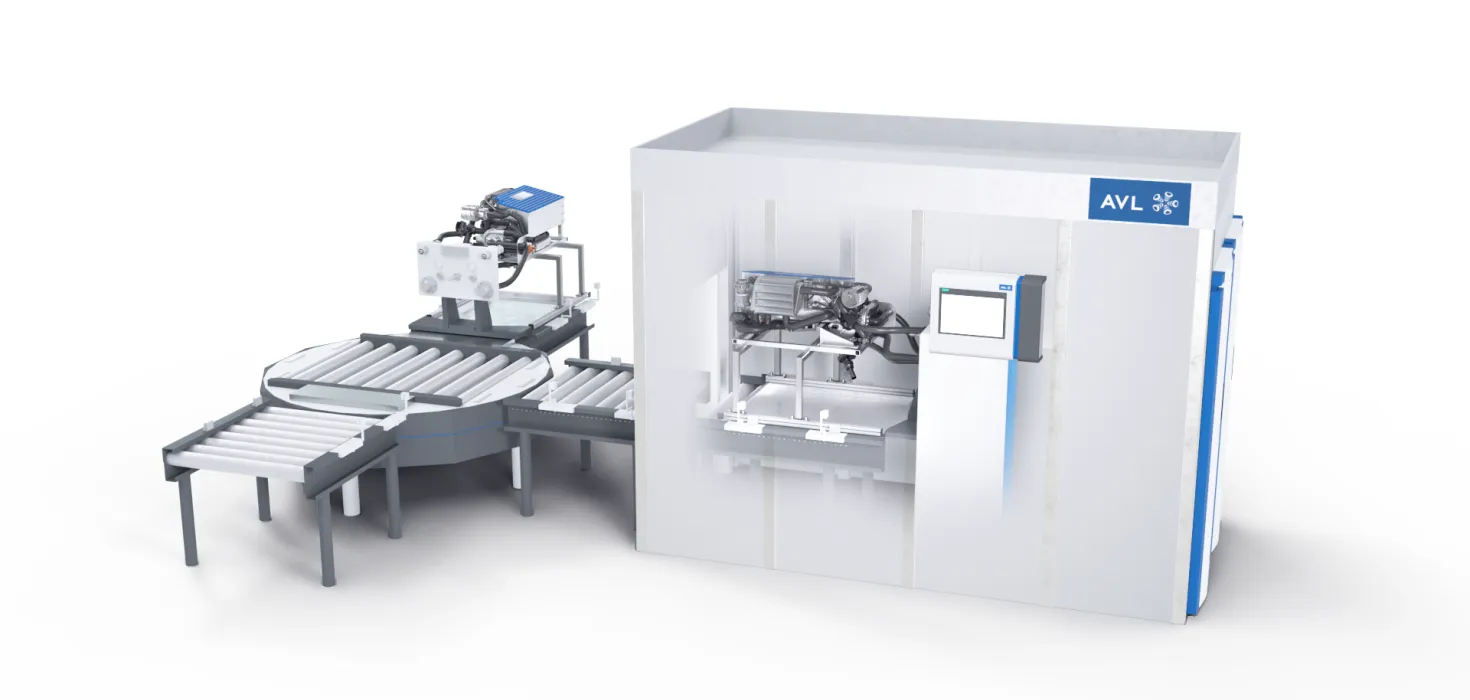

E-Motor Production Testing

AVL e-motor production testing solutions provide highest efficiency and quality in time. These solutions are based on development know-how and decades of experience in production testing.

Explore our solutions:

- AVL E-Motor TS™ Quality Audit

- AVL E-Motor TS™ Conformity of Production

- AVL E-Motor TS™ End of Line

E-Axle Production Testing

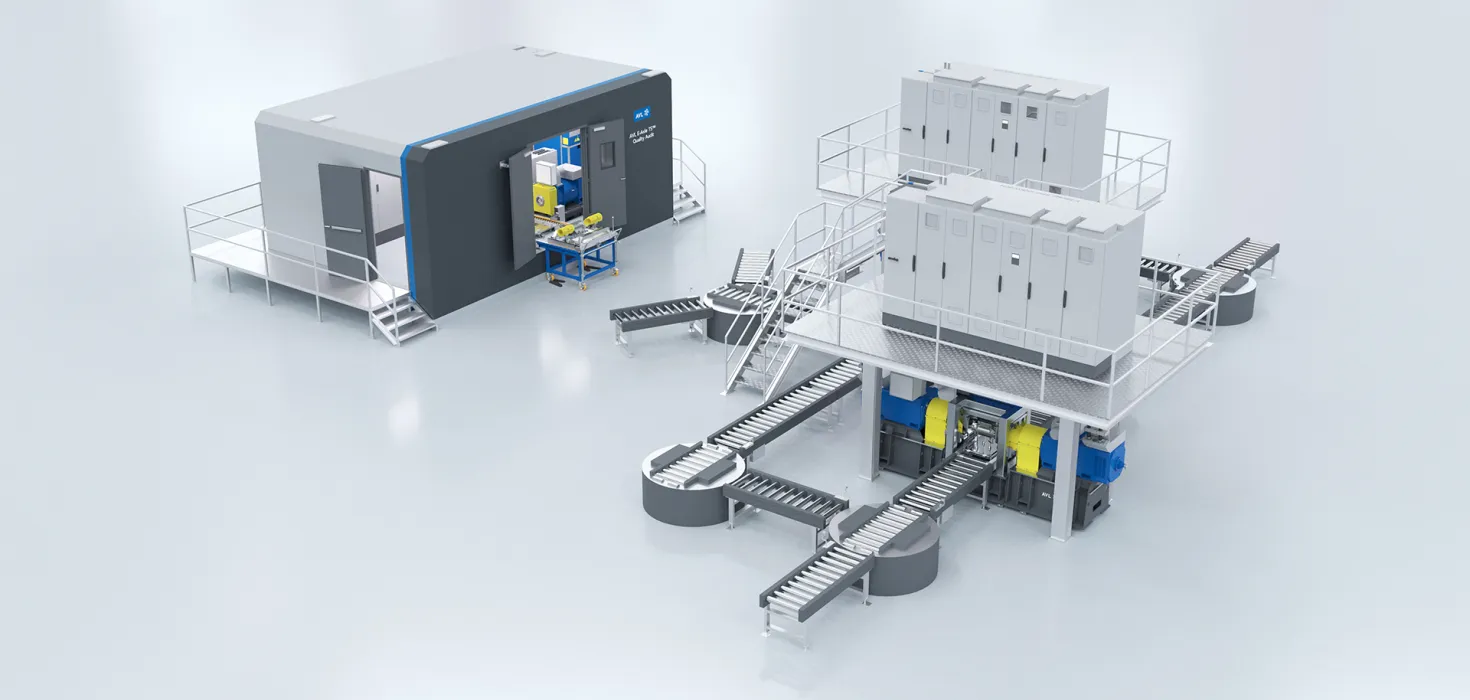

New ways in production testing provide highest efficiency and quality in time. With our in-house e-axle development know-how and decades of experience in production testing, we have developed AVL E-Axle Test Systems for production testing based on our philosophy of simplicity and robustness. We support you with customized test processes and appropriate test solutions.

- AVL E-Axle TS™ Quality Audit

- AVL E-Axle TS™ Conformity of Production

- AVL E-Axle TS™ End of Line

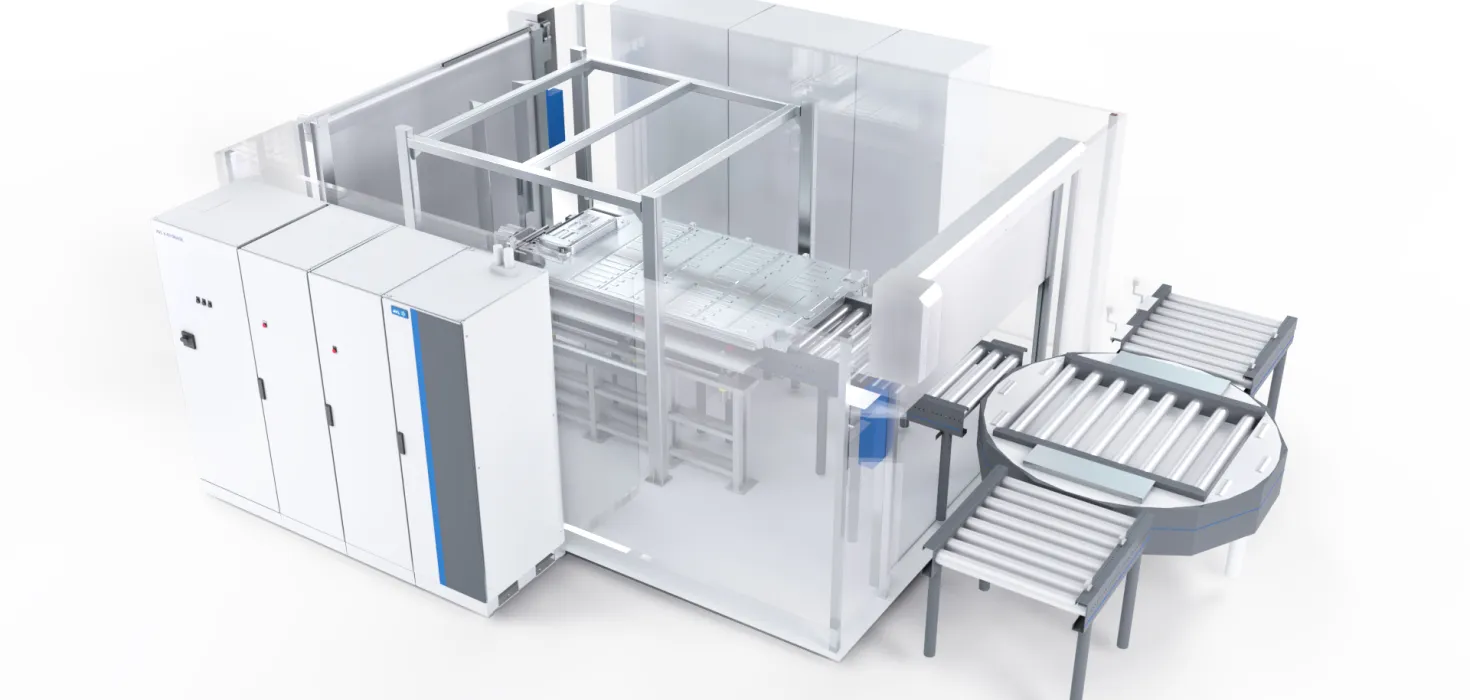

Battery Production Testing

To meet the demands of OEMs and their customers, batteries must combine performance with durability. Assembly quality needs to be high in all areas, including the cooling system, battery pack housing, module coupling, battery management system and high voltage connectors. Our solutions ensure integration, compatibility, and compliance with the highest automotive standards.

- AVL Battery-Module TS™ Quality Audit

- AVL Battery-Module TS™ Conformity of Production

- AVL Battery-Module TS™ End of Line

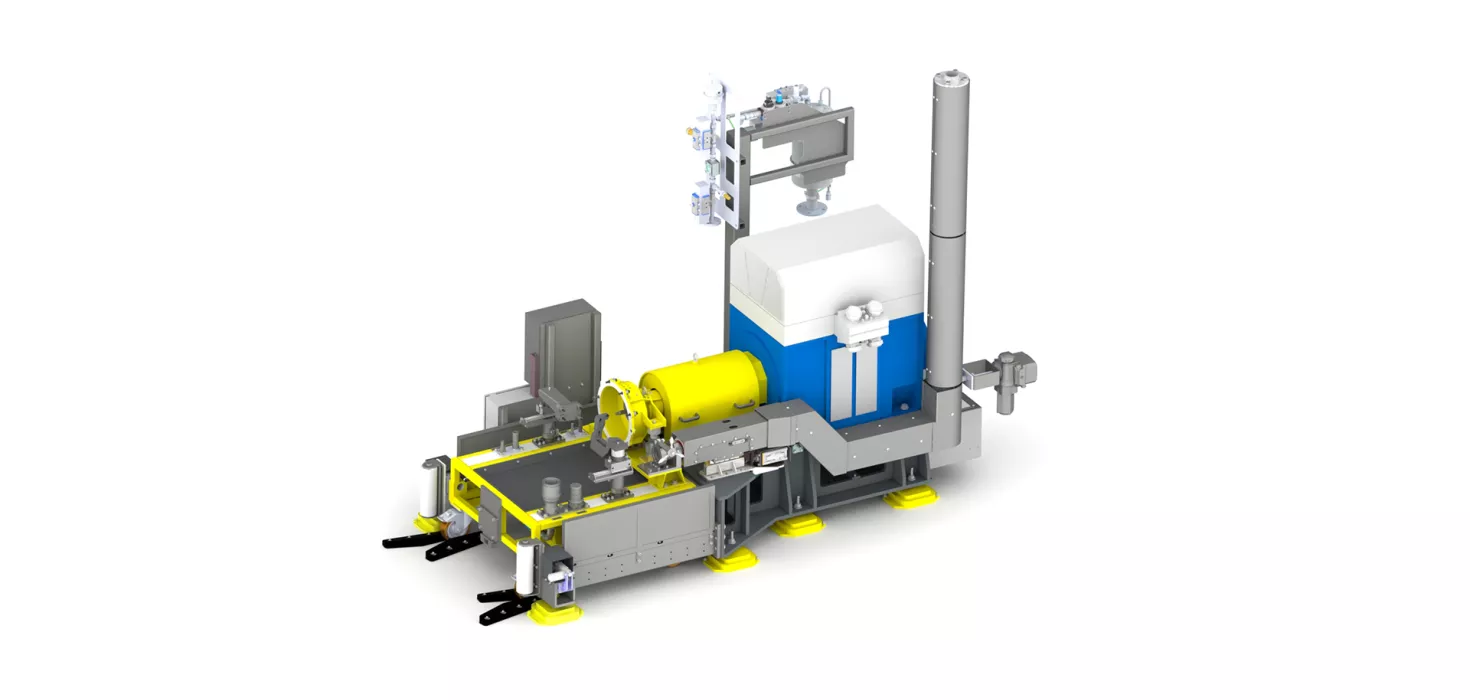

Fuel Cell Production Testing

To manage a complex and evolving technology such as fuel cell with increased time to market pressure requires innovative solutions and an independent partner to accelerate. AVL provides you with universal competence through the entire value chain of fuel cell commercialization. Our production test solutions are tailored to your specific production scenario and addressing the special requirements of the fuel cell.

- Fuel Cell Stack Testing Hot and Cold

- Fuel Cell System Testing Hot and Cold

Engine/Hybrid Production Testing

The holistic AVL quality assurance concept takes into account assembly and production constraints and provides complete system solutions to ensure best-in-class motor and process quality verification. As a reliable supplier, we support you in the design phase and provide additional input for your upcoming challenges. The solution portfolio includes test systems for gasoline, diesel, compressed natural gas (CNG), and hydrogen (H2) engines.

- AVL Engine TS™ Quality Audit

- AVL Engine TS™ Conformity of Production

- AVL Engine TS™ End of Line Hot

- AVL Engine TS™ End of Line Cold

NVH Production Testing

Comprehensive NVH data of a unit under test is a powerful tool in the production process. It reveals hidden insights and exposes quality issues that may otherwise go unnoticed. By analyzing the NVH signals during End-Of-Line testing, manufacturers can make data-driven decisions, leading continuous improvement and ensuring consistent, high-quality production. The End-of-Line Acoustic Quality Control System can handle complex NVH evaluations within the tight time constraints of an end-of-line environment.

AVL Production Testing Solutions – Brochure

Quality in Time.

AVL E-Mobility Testing Solutions – Brochure

Tested and Trusted.

AVL E-Axle TS™ EOL – Solution Sheet

Test Fast. Judge Confident.

AVL E-Axle TS™ QA / COP – Solution Sheet

Highest Flexibility. Complete Quality.

AVL Battery TS™ EOL – Solution Sheet

Improve production efficiency and avoid costly recalls.

- Decades of experience in country-specific and customer-specific norms and requirements for the automotive industry around the world.

- Support with standardization of equipment and processes for global acting manufacturers.

- Global service organization with local support at the customer site to ensure continuous production.

> 5000

employees worldwide for testing solutions.

> 7000

testbeds installed worldwide.

up to 99 %

maximum possible test system availability.

AVL List GmbH received the Global EcoVision Award from WKÖ in the presence of Federal Chancellor Karl Nehammer, Federal Minister Martin Kocher, and WKÖ President Harald Mahrer for the achievements in Hungary.

What kind of cars will we be driving in the future? These and other exciting questions around the topic of "Future Mobility" were addressed by more than 1,000 participants from 25 countries at the international 44th Vienna Motor Symposium. The tenor: Future automobiles will be CO2-neutral.

For his services, Prof. Helmut List was today awarded honorary citizenship of the city of Graz.

AVL generated 1.86 billion Euros in turnover last year – Eleven percent flows into research and development – 60 percent of the turnover is already generated by new technologies.