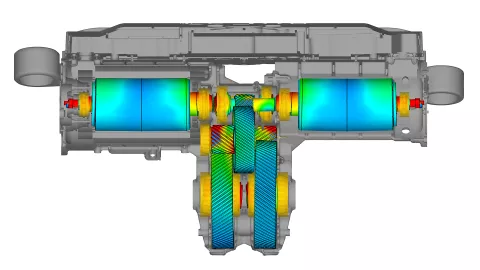

Modern e-axle concepts bring with them new types of design peculiarities. This can result in various disruptive effects.

For example, the bearing concept requires a detailed, simulative investigation. The tooth contact at the gearbox input leads to radial forces, which result in deformation or tilting of the rotor shaft. The electromagnetic field reacts strongly non-linearly to this and causes an increase in the eccentricity of the rotor. This should be supported by the rotor shaft bearings. A comprehensive evaluation with regard to NVH behavior is therefore only possible if the electric motor and the gearbox are taken into account in a simulation model.

Furthermore, common designs in e-axle systems provide for a plug-in sleeve with a gear wheel, which acts as the transmission input gear. This sleeve is pushed onto the rotor shaft via a spline. As a result of the tooth forces, a stick-slip effect can occur in the splines. This effect acts on the rotor shaft in the form of axial forces. It can have strong effects on the rotor bearing as well as excite complex system eigenmodes, which also influence the NVH behavior of the system.

Benjamin Schmelzle, Senior Simulation and Support Engineer, will show you in our free webinar how special vibration phenomena can be analyzed simulatively early in the development process. In the event of problems arising, design measures can thus be taken in good time.

Key topics and takeaways:

• Dynamic 3D multi-body simulation for analyzing NVH behavior with AVL EXCITE™ M

• Analysis of novel phenomena from the field of e-axis drives

• Influence of eccentricities on the rotor of the electric motor on its excitation behavior

• Investigation of various excitation phenomena of a mating toothing

• Influence of local deformations on the tooth contact of a spur gear stage