The profound technological shift towards e-mobility is driving battery development and testing. However, with limited capacity, new technologies and new applications, test field managers and test engineers are under tremendous pressure to maximize productivity and gain meaningful insights from the vast amounts of data generated during testing.

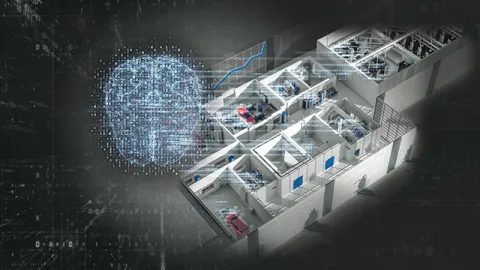

The challenges begin with the fact that project requirements from engineering often originate from disparate, unconnected systems and must be adapted for processing in the lab. When monitoring and tracking during test runs, it is important to ensure that data is collected in a structured and networked manner across all simulation and test systems. Relevant technical parameters must be extracted from the data. Automated and standardized reports provide the basis for comparable and traceable analyses. Only when everything is put together does a data package emerge that transparently maps the life cycle of a battery pack, including all tests down to the cell level.

In this free webinar, our experts will explain how our data and process management solution for batteries can support you in your demanding daily testing routine by storing and processing all your data in a way that is transparent and traceable for everyone involved in the process.

Look forward to the following highlights:

- Job management and automated test field planning

- Asset management including maintenance & calibration

- Monitoring and KPIs

- Data harmonization and automated reporting